Slitter Knife for Ultra Precision Shimless Line

ESR Purified Raw Material

Ultra Precision Tolerance

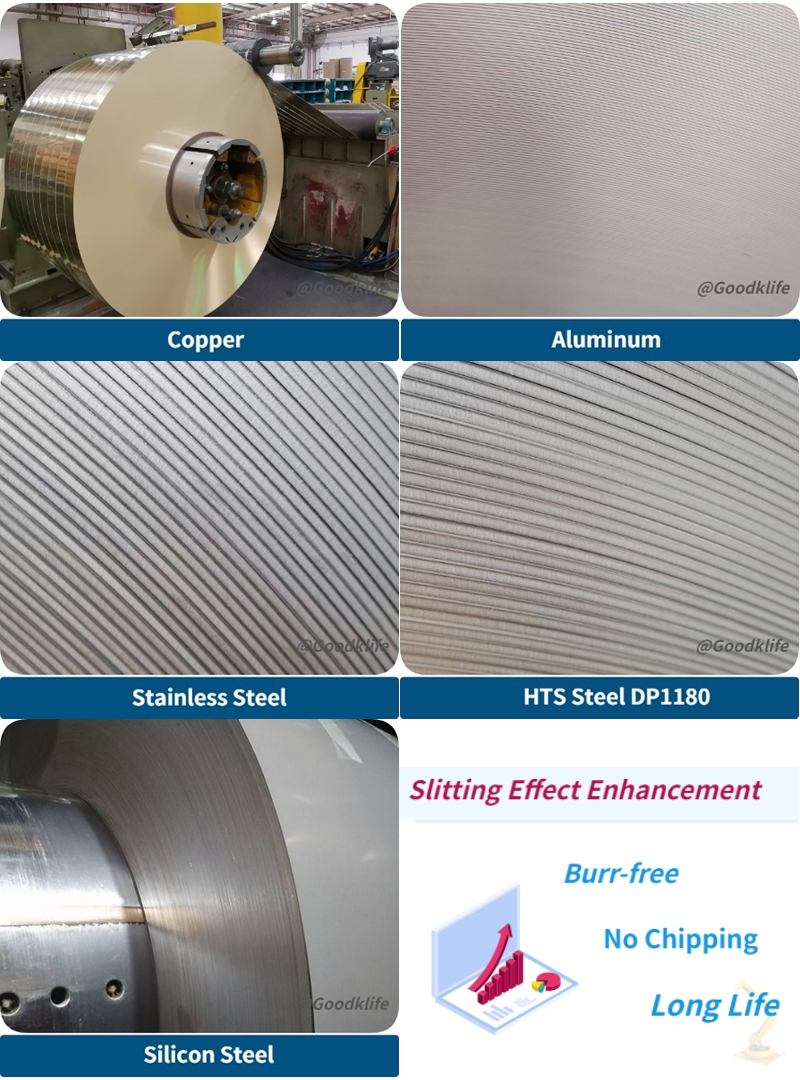

Long Lasting Sharpness

Bur-free Slitting

Ultra Precision Tolerance

Long Lasting Sharpness

Bur-free Slitting

Description

Detail Parameters

PRODUCTS DESCRIPTION |

|

||

| QR Code Quick Identification of Information Efficient Knives Management Recording of Regrindning Cycles Usage Tracking Robot Operation |

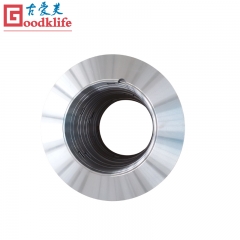

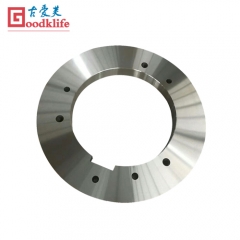

Keyway/I.D./Dirt Groove Chamfered Easier Installation Operator Protection Arbors Protection Precise Dirt Groove for Robot Operation |

Marks

Detailed Marking Easy Tool Selection Marking Thickness in the Dirt Groove for Permanent Retention

"+", "0", "-" Marks for Further Improvement of Slitting Accuracy

|

| PRODUCT PARAMETER | |

| Brand |

Goodklife |

|

Material |

TC, HSS, Tool Alloy Steel (refer to Material Recommendation Sheet) |

|

Thickness |

+/- 0.0010 mm |

|

Size |

Customized |

|

Parallelism |

0.002 mm |

|

Flatness |

0.002 mm |

|

O.D. |

+/- 0.01 mm or as request |

|

I.D. |

H6 or as request |

|

Dirt Groove |

Yes or as request |

|

Keyway |

as request |

|

Heat treatment |

thorough-hardening |

|

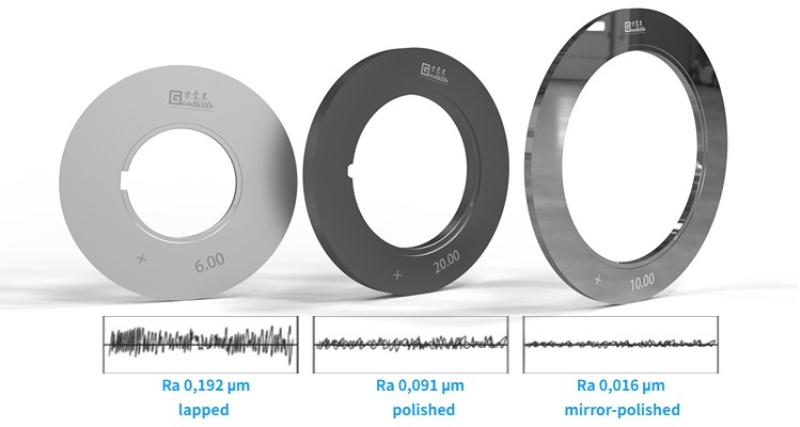

Surface Quality |

Precision Ground/Lapped/Polished/Mirror Polished |

|

| Material Code | Thickness Range/mm | ||||

| up to 0.6 | up to 1.5 | up to 3 | up to 6 | more than 6 | |

|

cold rolled steel

|

G8, G6 | G8, G1 | G1, G2 | G1, G2 | |

| hot rolled steel | G1, G2, G4 | G1, G2 | |||

| stainless steel | G24, G25 | G1, G2 | G1, G2 | ||

| silicon steel | G18 | G24, G25 | G1, G37 | ||

| non-ferrous | G6, G24 | G6, G24 | G1, G8 | G1, G2 | |

|

OUTSTANDING PERFORMANCES |

|

Depending on your budget and requirements, our team of experts will develop a customized solution for you, including but not limited to the selection of slitting tool materials, accuracy, etc. If necessary, our field team will come to your company to study the current cutting problems and improve your cutting quality.

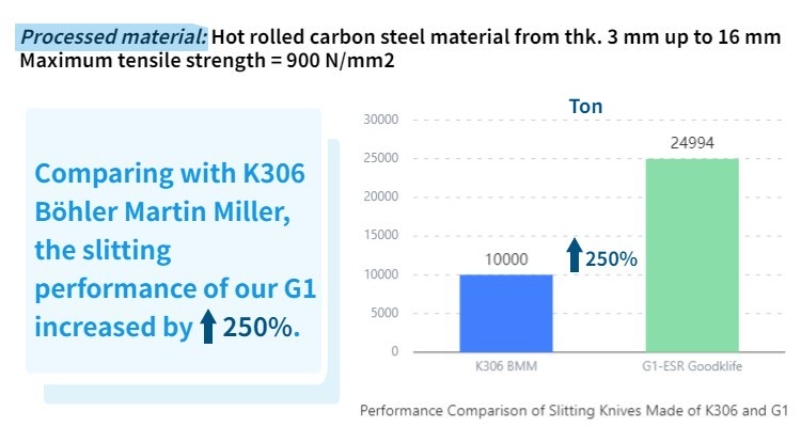

INCREASED LIFESPAN & COST SAVINGSBy selecting the right raw material for the slitter knife and combining it with proven heat treatment processes, we can produce knives that will last significantly longer and thus reduce your tool purchase costs.

|

PRECISE STRIP WIDTH CONTROLUltra-high precision slitting tools help you achieve perfect strip width control. The application of "+", "0" and "-" marks further improves the cutting accuracy.

|

| width of the 2nd strip 27.95 mm | width of the 6th strip 27.95 mm | width of the 9th strip 27.95 mm |

EDGE QUALITY CONTROLSuitable raw materials for tools and advanced production processes ensure continuous sharpness of the slitter knives. Ultra-high precision slitting tooling ensures dynamic and stable upper and lower knives clearance.

|

QUALITY ASSURANCE |

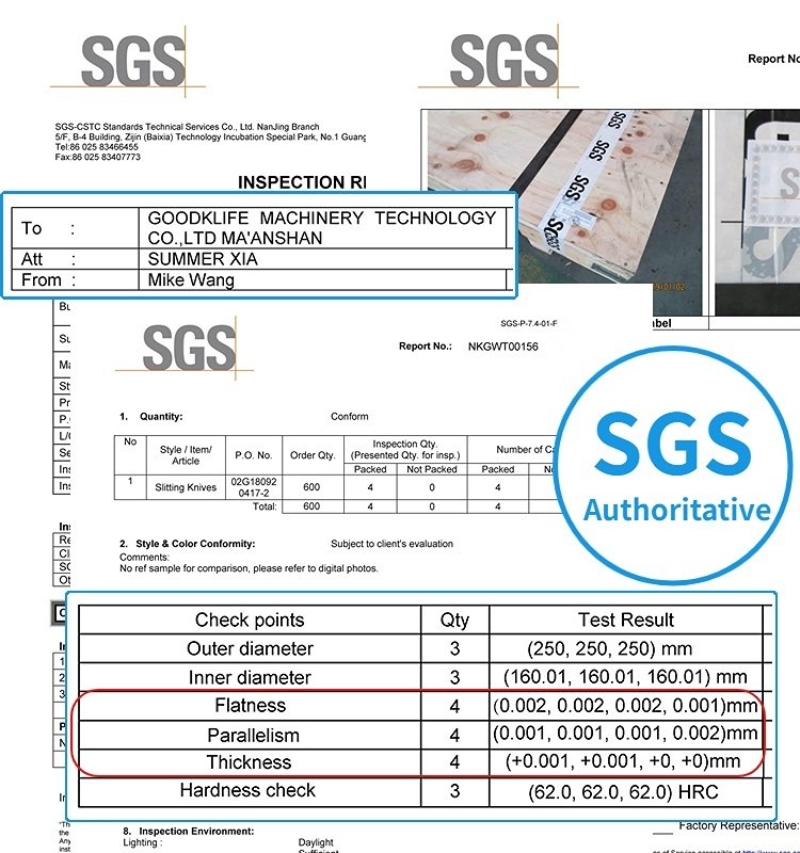

SGS AUTHORITATIVE TESTINGGoodklife has always been committed to providing high-quality, ultra-high-precision cutting tools to customers around the world. In order to enhance mutual trust, for the first cooperation, we now provide free SGS testing services to invited customers to dispel all your doubts. |

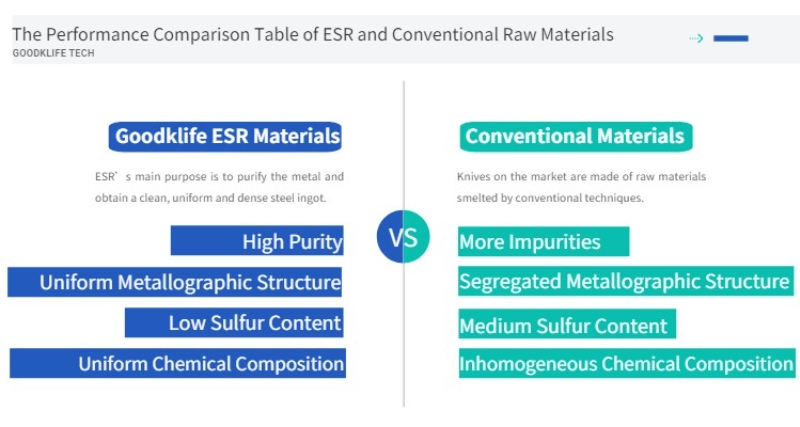

MATERIAL QUALITY ASSURANCERaw material is the foundation of knife quality. Goodklife has the most complete range of blade raw materials in the world. We will recommend the most suitable blade material according to the customer's detailed cutting conditions to ensure that the blade is lastingly sharp without chipping. In order to meet the growing demand for high-strength steel shearing, Goodklife has also developed the national patented material G1, which greatly improves the shearing effect.At present, the vast majority of knives on the market are made of raw materials smelted by conventional techniques. In order to further improve the quality of the raw materials for the knives, Goodklife only selects raw materials produced by the ESR process. The ESR process is a further purification of raw materials after the conventional steelmaking process. Compared with raw materials smelted by conventional methods, ESR raw materials can largely avoid the phenomenon of chipping, and can also significantly improve the service life of the blade. |

HEAT TREATMENT ASSURANCEGoodklife's heat treatment workshop is fully equipped with various heating, annealing, quenching and tempering equipment, and is equipped with a number of experienced professional senior engineers. After years of experience summarization, the company's unique heat treatment process has been formed. Blades with a thickness of less than 100 mm can be fully hardened into the core, which can ensure that the performance of the blade is the same until it is ground to the min. size. Not only the safety factor of the blade is high, but also the production efficiency can be significantly improved and the cutting cost can be reduced. |

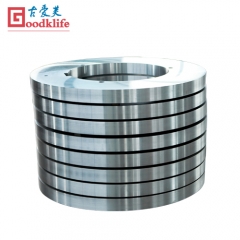

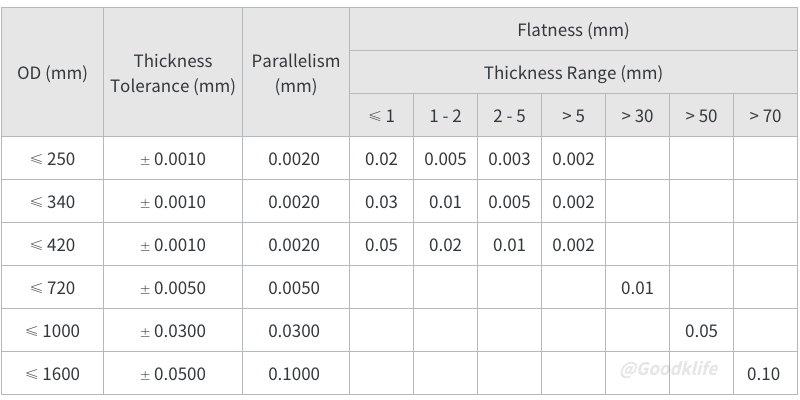

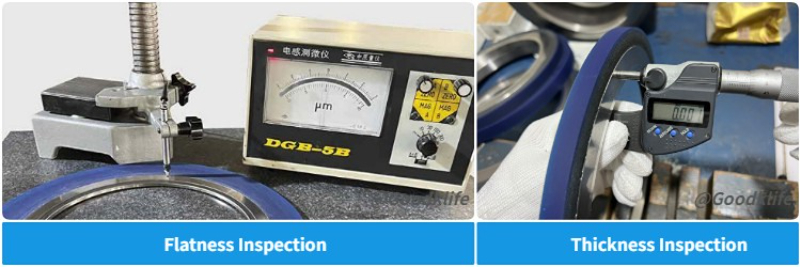

PRECISION TOLERANCE ASSURANCEGoodklife ultra-high precision slitting knives are more like works of art. The company currently has a number of ultra fine grinding machines and lapping machines. Every employee in the finishing workshop is deeply rooted in the pursuit of high precision, and strictly abides by the operating system to ensure that every slitting tool is qualified. |

GOODKLIFE BRAND STORY |

GOODKLIFE - THE CHOICE OF PROFESSIONAL QUALITY

COMPANY PROFILE |

||

GOODKLIFE HISTORY1988 As one of the first companies producing metal shear processing tools in China, we have been continuously exploring high quality products.

2006 Successfully developed a new tool high-strength steel G1, which greatly improved the service life of metalworking tools. The material was awarded the national new invention patent in 2008. 2011 We started to enter the international market, and now our products are selling well in many countries

|

HIGH PRECISION TOLERANCE1998 Started mass production of slitting tools with a thickness accuracy of +/-0.005 mm and parallelism 0.01 mm accuracy.

2000 Started mass production of slitting tools with a thickness accuracy of +/-0.005 mm and parallelism 0.005 mm accuracy. 2003 Started mass production of slitting tools with a thickness of +/-0.003 mm and parallelism & flatness 0.005 mm accuracy. 2016 We started mass production of slitting tools with thickness +/-0.001 mm and parallelism & flatness 0.002 mm accuracy. |

|

|

| PRODUCT | |

| Brand | Goodklife |

| Material | TC, HSS, Tool Alloy Steel (refer to Material Recommendation Sheet) |

| Thickness | +/- 0.0010 mm |

| Size | Customized |

| Parallelism | 0.002 mm |

| Flatness | 0.002 mm |

| OD | +/- 0.01 mm or as request |

| ID | H6 or as request |

| Dirt Groove | Yes or as request |

| Keyway | as request |

| Heat treatment | thorough-hardening |

| Surface Quality | Precision Ground/Lapped/Polished/Mirror Polished |

| CHARACTERISTIC | |

| Specialized for | design for supper high quality bur-free slitting |

| PACKAGING | |

| Inner packaging | applied with anti-rust oil, packed in plastic bag separately or as request |

| Outer packaging | cardboard case/plywood case or as request to be packed solidly suitable for long distance marine transportation and multi-handling and well protected against dampness, moisture, shock, rust and rough handling. We will be liable for any expense and loss attributable to inadequate or improper protective measures taken by us in regard to the packing. |

| Mark & Sign | on the surface of each package the package number, measurement, gross weight , net weight and the wordings "RIGHT SIDE UP"' , "HANDLE WITH CARE", "KEEP DRY", and the above shipping mark will be stenciled with fadeless paint. |

| DOCUMENTS & CERTIFICATE | |

| Commercial Documents | commercial invoice/packing list/insurance policy/certificate of origin/full set of bill of lading |

| Quality Certificates | inspection certificate/raw material data sheet/quality certificate/heat treatment certificate/certificate of quality/certificate of quantity |

| Inspection Report by the third party | SGS/TUV/SAG or as request |

| PAYMENT TERMS | |

| Official Payment | letter of credit (L/C)/payment against documents/TT or as request |

| Quick Payment | western union/credit card/Paypal/alipay/wechat or as request |

| DELIVERY TERMS | |

| Special Service (DDP/DDU) | door to door (by courier/by sea/ by air/by train/by bus or combined transportation) our experienced transportation team provides door to door service, including customs clearance in destination country. |

| Standard Service | FOB/CFR/CIF/FCA or as request |

Maybe you like

aaa

Sep 08, 2022

aa

1

Review