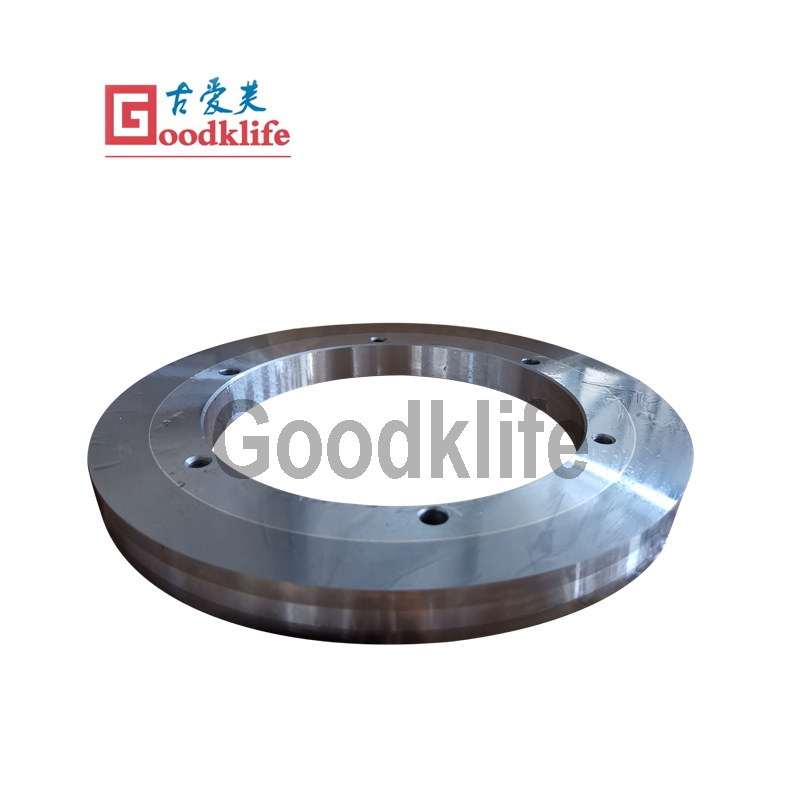

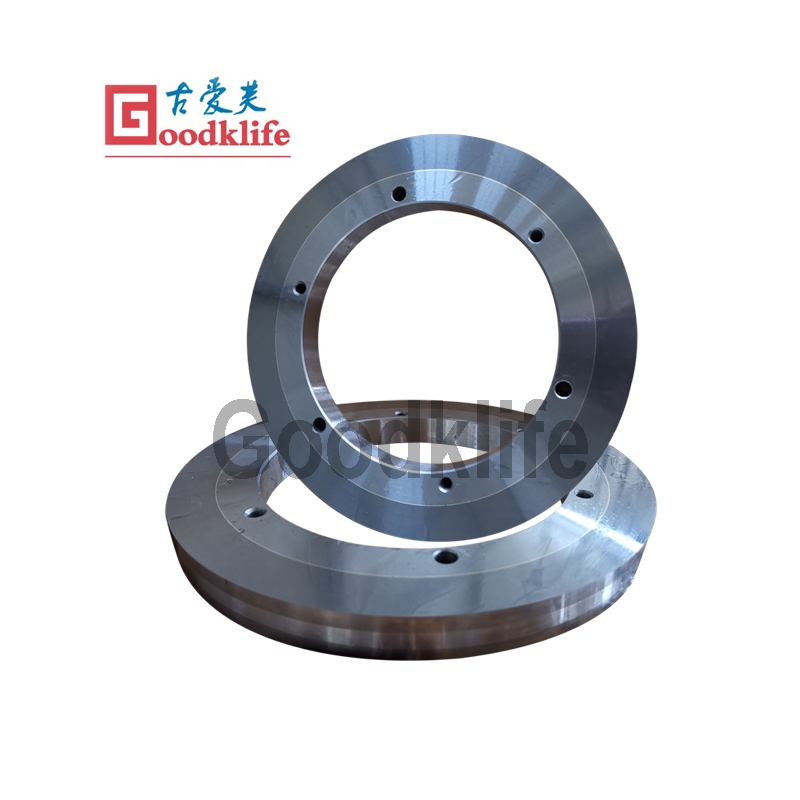

Circular slitter knives for cutting electrial silicon steels

Item No.: GSX0111069

Silicon steel is one of the most difficult steels to cut, especially oriented silicon steel, also called cold rolled transformer steels. Goodklife has more than 32 years experience in manufacturing cutting blades, its tungsten carbide material and high sp

Description

|

Goodklife Machinery Technology Co., Ltd Ma’anshan is located in Bowang Town which is one of the most famous town for blades in China, Goodklife has more than 30 years experience in this line. The company has been committed to providing knives and blades of high productivity and high precision. From raw material, heat treatment to finishing, Goodklife keeps track and exercises strict control over every piece, in order to improve the performance of our products and production efficiency, at the same time reduce the production cost.

|

Silicon steel sheet, also called silicon lamination, it is a kind of ferrosilicon soft magnetic alloy with very low carbon content, generally with a silicon content of 0.5 to 4.5%. It is mainly used to make iron cores for various transformers, motors and generators. Adding silicon can increase the resistivity and maximum permeability of iron, reduce coercivity, core loss (iron loss) and magnetic aging.

According to the manufacturing process and purpose, electrical steel is divided into three categories: hot-rolled silicon steel, cold-rolled electrical steel and special-purpose silicon steel.

Non-oriented silicon steel

Ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its crystal grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually supplied in coils of cold-rolled plates or strips, with common thicknesses of 0.35 and 0.5mm, which are mainly used to manufacture motors and generators.

Oriented silicon steel, also called cold rolled transformer steel, is an important ferrosilicon alloy used in the transformer (iron core) manufacturing industry. Cold rolled oriented silicon steel is mainly used to make transformer cores. The common thicknesses of cold-rolled oriented silicon steel sheets for transformers are 0.20, 0.30, 0.35, and 0.50mm, and their silicon content is generally high.

During the processing of silicon steel sheet, the original lattice structure of silicon steel sheet is destroyed, which will affect the performance of the transformer steel. Therefore, it is necessary to improve the shear quality of the silicon steel sheet, reduce the burr of the silicon steel sheet, and at the same time improve the flatness of the silicon steel sheet, and apply an appropriate clamping force to the core column.

Material selection

Circular knives for cutting stainless steel are mainly made of high-quality tungsten carbide like Goodklife G16, G17, G18, G19 and high speed steels such as W6Mo5Cr4V2(G24)) and W18Cr4V(G25). The incision is smooth and the cutting edge is very sharp. Goodklife can produce ultra-high-precision circular knives which outside diameter smaller than 500mm. OD smaller than 300mm, the thickness tolerance can reach ±0.001mm.

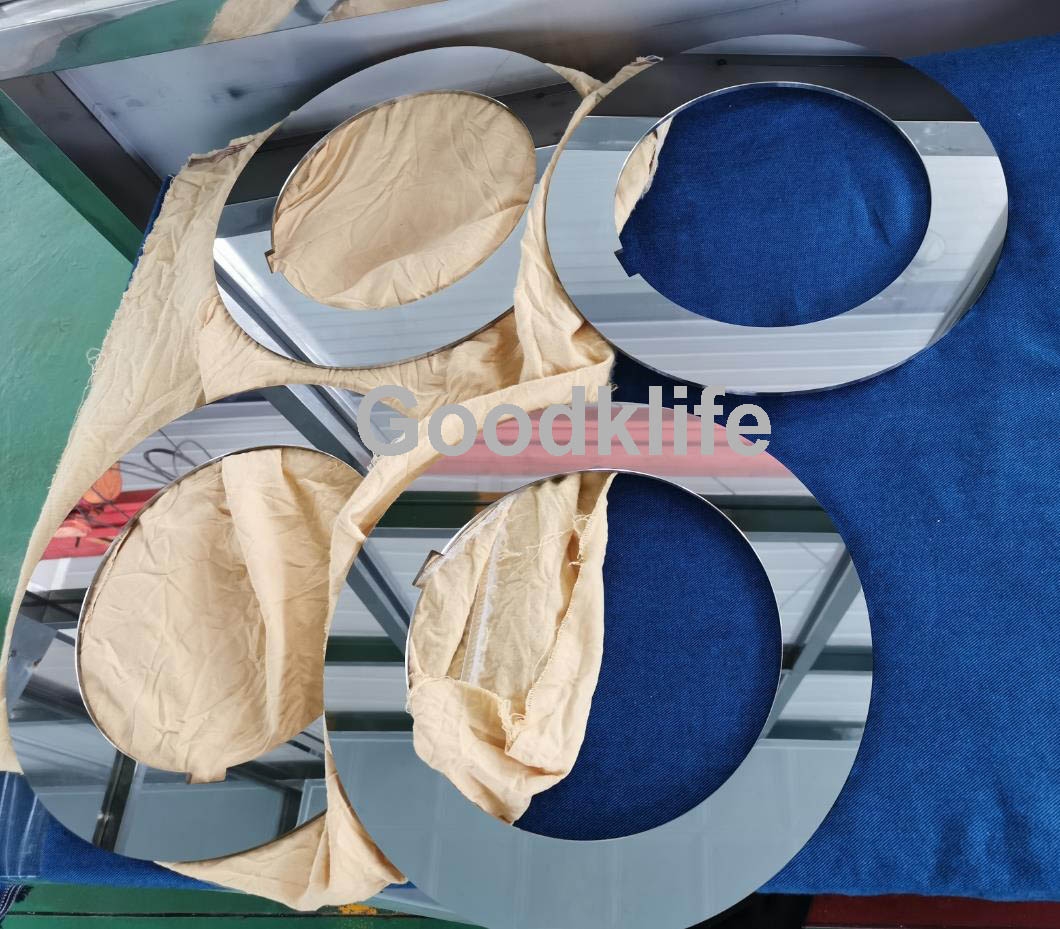

The quality management of cutting tools is an important task that cannot be ignored. Our company always regards product quality and service as the company's primary goal. In the production management process, the products are strictly implemented in accordance with the quality management system. Make full use of CMM, 2D imager, imported altimeter, torsion spring multimeter and other inspection equipment, accurately control every detail, every process, and ensure the superiority of every product.

Goodklife has more than 6 lapping machines, knives OD max 400mm and thickness max 50mm can do the lapping process in our factory.

Ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its crystal grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually supplied in coils of cold-rolled plates or strips, with common thicknesses of 0.35 and 0.5mm, which are mainly used to manufacture motors and generators.

Oriented silicon steel, also called cold rolled transformer steel, is an important ferrosilicon alloy used in the transformer (iron core) manufacturing industry. Cold rolled oriented silicon steel is mainly used to make transformer cores. The common thicknesses of cold-rolled oriented silicon steel sheets for transformers are 0.20, 0.30, 0.35, and 0.50mm, and their silicon content is generally high.

During the processing of silicon steel sheet, the original lattice structure of silicon steel sheet is destroyed, which will affect the performance of the transformer steel. Therefore, it is necessary to improve the shear quality of the silicon steel sheet, reduce the burr of the silicon steel sheet, and at the same time improve the flatness of the silicon steel sheet, and apply an appropriate clamping force to the core column.

Material selection

Circular knives for cutting stainless steel are mainly made of high-quality tungsten carbide like Goodklife G16, G17, G18, G19 and high speed steels such as W6Mo5Cr4V2(G24)) and W18Cr4V(G25). The incision is smooth and the cutting edge is very sharp. Goodklife can produce ultra-high-precision circular knives which outside diameter smaller than 500mm. OD smaller than 300mm, the thickness tolerance can reach ±0.001mm.

The quality management of cutting tools is an important task that cannot be ignored. Our company always regards product quality and service as the company's primary goal. In the production management process, the products are strictly implemented in accordance with the quality management system. Make full use of CMM, 2D imager, imported altimeter, torsion spring multimeter and other inspection equipment, accurately control every detail, every process, and ensure the superiority of every product.

Goodklife has more than 6 lapping machines, knives OD max 400mm and thickness max 50mm can do the lapping process in our factory.

|

|

Tungsten carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance and corrosion resistance, especially its high hardness and wear resistance, which remain basically unchanged even at a temperature of 500°C , It can remain high hardness at 1000°C.

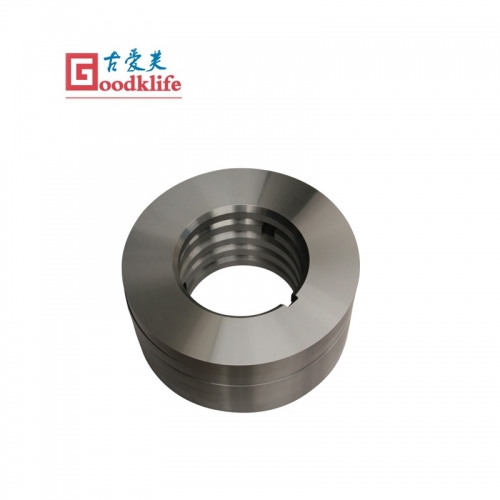

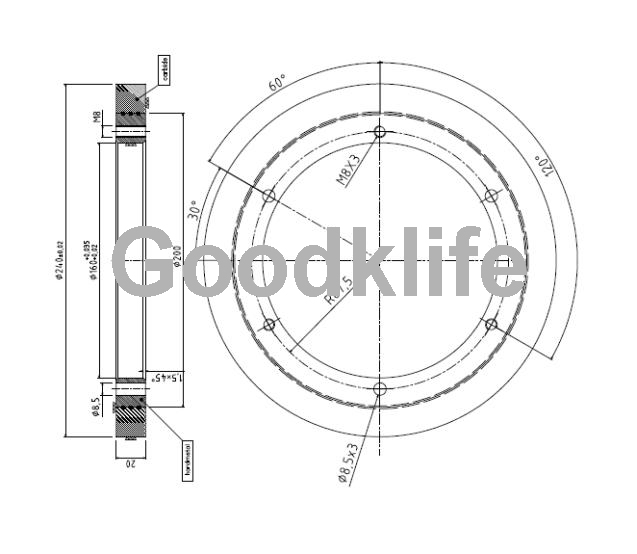

1. Tungsten carbide slitter knives

Tungsten carbide slitter knives are suitable for all kinds of thin plate slitting lines.

Technical requirements:

1. Tungsten carbide slitter knives

Tungsten carbide slitter knives are suitable for all kinds of thin plate slitting lines.

Technical requirements:

| Parallelism | Flatness | TH tolerance |

| 0.002mm | 0.002mm | ±0.001mm |

|

|

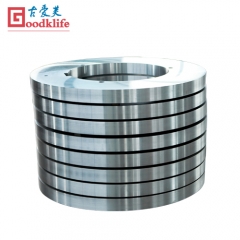

2. THREE POINT SLITTING LINE BLADE

Goodklife has its unique THREE POINT SLITTING LINE BLADE. Slitter knives can cut silicon steel sheets from 100,000 meters to 300,000 meters per sharpening, while with burrs <0.02mm.

Standard size:

Goodklife has its unique THREE POINT SLITTING LINE BLADE. Slitter knives can cut silicon steel sheets from 100,000 meters to 300,000 meters per sharpening, while with burrs <0.02mm.

|

| Φ160.5 x Φ90 x 52 | Φ160.5 x Φ100 x 52 |

| Φ160.5 x Φ110 x 52 | Φ175.5 x Φ110 x 60 |

| Φ198.5 x Φ120 x 66 | Φ200.5 x Φ128 x 75 |

| Φ208.5 x Φ120 x 75 | Φ230 x Φ125 x 85 |

| Φ250×Φ125x 85 | Φ270 x Φ140 x 90 |

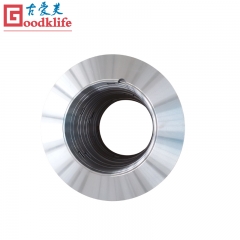

3. Tungsten carbide insert slitter knives

Due to the disadvantages of the solid tungsten carbide blades being difficult to re-grind and the production cost is high, our company adopts unique inlay technology to make the cemented carbide inlay on the low-carbon steel knife body, which can not only maintain the original performance of the cemented carbide, but also has low The toughness of carbon steel meets customers' requirements for sharp, durable and economical blades to the greatest extent. The carbide insert knife is welded at high temperature and ground with diamond grinding wheel, the hardness reaches HRA 88-90, and the durability is 5-10 times that of ordinary HSS high-speed steel, which significantly reduces the number of knife sharpening and improves production efficiency.

|

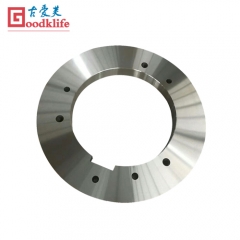

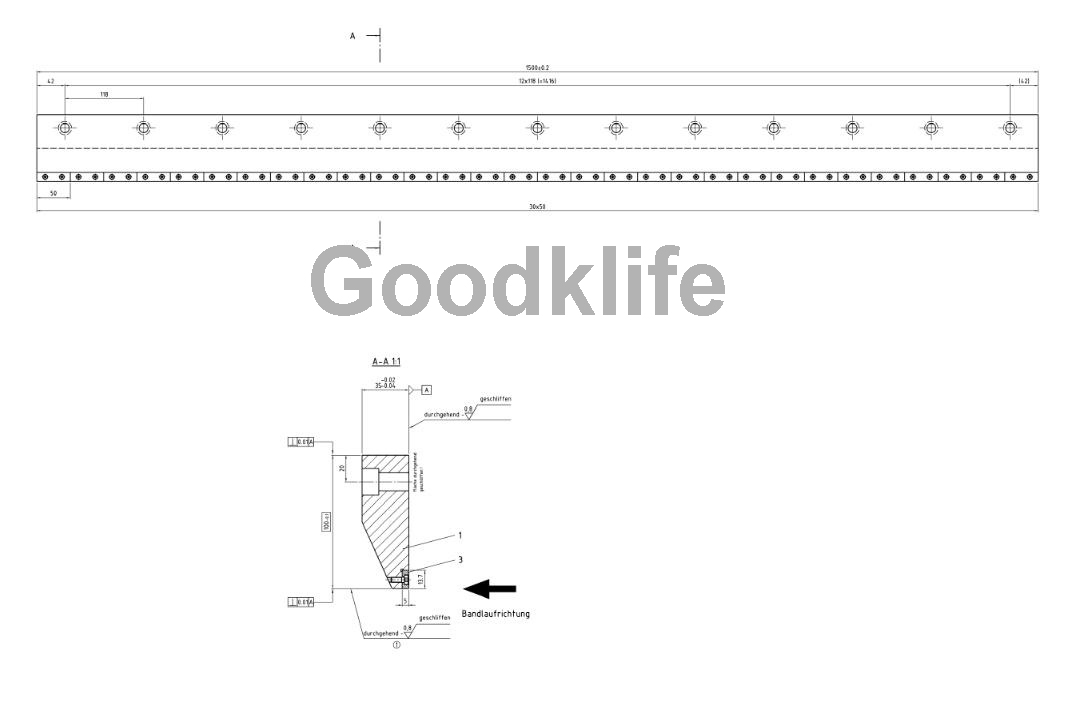

4. Cut to length blades

Adapt to Georg, Sueneng, Aston, etc.

1000 cut to length line, 800 cut to length line, 600 cut to length line, 500 cut to length line, 400 cut to length line.

Technical requirements: straightness≤0.01mm, parallelism≤0.01mm, etc.

Thickness tolerance < 0.003mm, each time sharpening can cut 0.23 to 0.5mm silicon steel 2.5 million times to 3 million times, and the burr is less than 0.02mm.

Case 1--Slitter knives Φ250*Φ160*10, we choose G18 tungsten carbide material which is similar with YG15, the hardness is HRA88. And according to customer feedback, it can cut 200,000 meters.

Adapt to Georg, Sueneng, Aston, etc.

1000 cut to length line, 800 cut to length line, 600 cut to length line, 500 cut to length line, 400 cut to length line.

Technical requirements: straightness≤0.01mm, parallelism≤0.01mm, etc.

Thickness tolerance < 0.003mm, each time sharpening can cut 0.23 to 0.5mm silicon steel 2.5 million times to 3 million times, and the burr is less than 0.02mm.

|

|

|

Setting of knives' clearance and overlap

The related transmission equipment of the disc cutter is automatically adjusted to the set value according to the received CRT data, and the set value of the disc cutter clearance and overlap amount sent to the CRT process computer system is obtained by the following model,

A=a1X+b1Y+c1Z+d1P

B=a2X+b2Y+c2Z+d2P

Where A is the clearance, B is the overlap amount, X is the thickness of the incoming material (mm), Y is the yield strength of the product (N/mm²), Z is the diameter of the disc blade (mm), and P is the brand.

The range of coefficients is as follows:

The related transmission equipment of the disc cutter is automatically adjusted to the set value according to the received CRT data, and the set value of the disc cutter clearance and overlap amount sent to the CRT process computer system is obtained by the following model,

A=a1X+b1Y+c1Z+d1P

B=a2X+b2Y+c2Z+d2P

Where A is the clearance, B is the overlap amount, X is the thickness of the incoming material (mm), Y is the yield strength of the product (N/mm²), Z is the diameter of the disc blade (mm), and P is the brand.

The range of coefficients is as follows:

| Overlap | Clearance | ||||

| Thickness | a1 | 0.074~0.084 | a2 | -0.00118~-0.00157 | |

| Yield strength | b1 | -0.00025~-0.00035 | b2 | 0.00011~0.00030 | |

| OD of slitter knife | c1 | 0.00029~0.00036 | c2 | 0.00045~0.00064 | |

| Steel grade | d1 | 0.09~0.13 | d2 | 0.689~0.733 | |

According to the above, the clearance is in the range of 0.035-0.01mm. The reason is that when cutting common materials, the side clearance of the disc is usually 7-10% of the plate thickness. However, due to the thin material and high hardness of oriented silicon steel, the value of the side clearance is 0.035-0.01mm according to actual field experience.

In addition, the overlap amount should be taken as 0.35-0.15mm, the reason is: generally according to experience, the overlap amount is 1/2 to 1/3 of the thickness of the strip. However, in the actual production process of oriented silicon steel, it is often encountered that the scrap edge is cut continuously, or there are small edge waves after the edge is cut. Therefore, the amount of disc shear overlap is 0.35-0.15mm.

Comparison table of grade coefficients of oriented silicon steel.

In addition, the overlap amount should be taken as 0.35-0.15mm, the reason is: generally according to experience, the overlap amount is 1/2 to 1/3 of the thickness of the strip. However, in the actual production process of oriented silicon steel, it is often encountered that the scrap edge is cut continuously, or there are small edge waves after the edge is cut. Therefore, the amount of disc shear overlap is 0.35-0.15mm.

Comparison table of grade coefficients of oriented silicon steel.

| Steel grade | B30P110 | B30P105 | B30P100 | B27P100 | B27P095 | B27P090 | B23R090 | B23R085 | B23R080 |

| % | 0.02 | 0.023 | 0.025 | 0.025 | 0.028 | 0.03 | 0.03 | 0.033 | 0.034 |

Maybe you like

Review