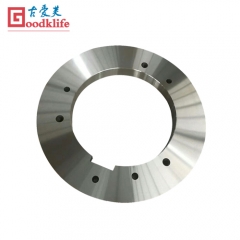

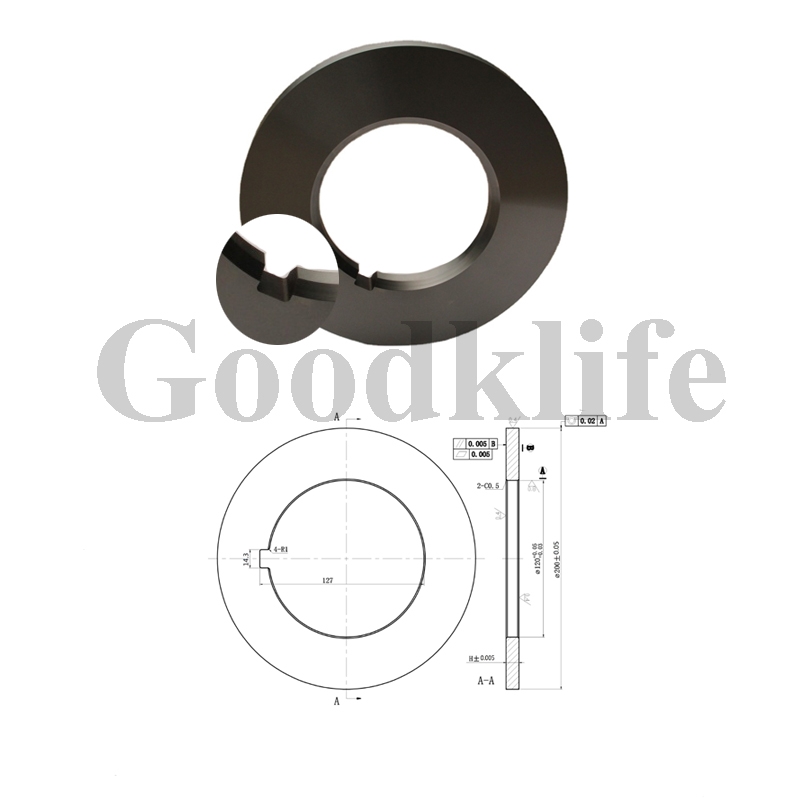

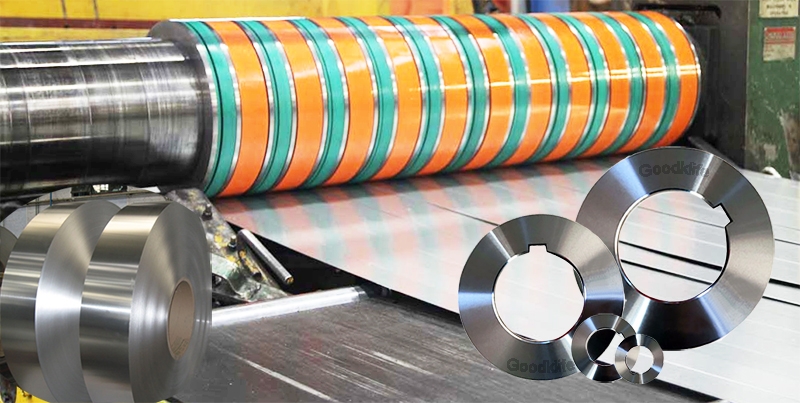

Slitting Blades for Steel Coil

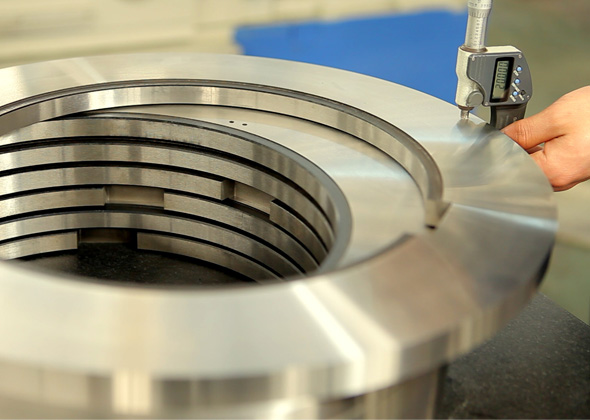

We manufacture slitting blades up to 1500 mm ( 59.06 inches ) in diameter for slitting and side trimming lines. Slitting blades can cut 1.2-25mm thick hot rolls and 0.2-4mm thick cold rolls.

Description

Detail Parameters

| SLITTING BLADES FOR STEEL COIL |

|

Cutting material:Steel Coil

|

| PRODUCT INFORMATION |

| Brand | Goodklife |

| Origin | Ma’anshan China |

| Series | Steel Coil |

| Material | ESR Purified Raw Material - G1 |

| External tolerance | +/- 0.01-+/- 0.02 mm |

| Inner diameter tolerance | H6, H7 |

| Surface finish | Ra=0.2, 0.4 um |

| SPECIAL SLITTING BLADES FOR STEEL COIL |

|

| Slitting machine blade material Due to the anti-shearing and abrasion between the blade and the plate, the blade will produce a metal surface fatigue layer, and the choose material of the blade can extend its service life as much as possible. At present, the common blade materials are: A. SKD-11 (Cr12Mov), SKD-12 (high hardness cold die alloy steel), SLD-11 are the most advanced digital materials in this series

B. SKH-9, SK-51, SK-31, SK-48, SK54, etc. (Molybdenum series high-speed tool steel) C. SKD-4, SKD-5, etc. (low hardness cold die alloy steel) Analysis of metal elements of the blade material and applicable plates:

A. SKD-11 (Cr12Mov): its carbon content is between 1.4 and 1.6, and the chromium content is between 11.00 and 13.00. Compared with other alloys, its Mo content and V content have higher hardness (it can reach Hardness range 58°-60°), toughness and wear resistance, suitable for the following plates: ① Cold rolled plate (SPCC) 0.3 ~ 3.2; ② Surface treatment board (electrolytic, galvanized, color, etc.) 0.3 ~ 3.2; ③ Stainless steel (SUS) 0.1~1.0. B. SKD-4: With high nickel content and high toughness, it is suitable for shearing thick hot-rolled plates and high-tension plates, but has poor wear resistance. C. SKD-5: It is between SKD-4 and SKD-11, suitable for mid-slab cutting.

D. SKH-51: High content of tungsten, molybdenum and vanadium. It is the same series of molybdenum high-speed tool steel (SKH-9) with SKH-54, which has high wear resistance. HRC60°~63° E. SKH-54: It is a higher grade material of SKH-9 series, HRC61°~64°.

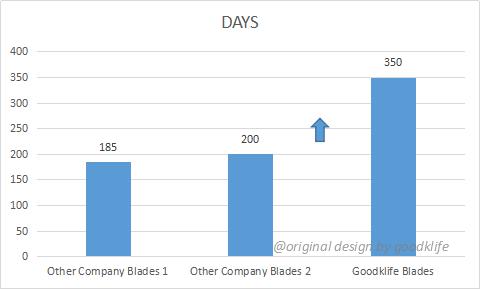

E. New Material G1 is a patented material of Goodklife Company, which belongs to low-carbon high-alloy special steel, specially designed for (ultra) high-strength steel. Compared with traditional blade materials, its cutting life is significantly improved.

Fig. 1 Service life comparison table Service life comparison

Figure 1 is customer purchase slitting blades for cutting 1.0mm SPCD material. Three companies were purchased to compare the service life. G1 is our patent material. It is designed to cut medium-size thickness steel sheet. It has excellent performance of wear-resistance and toughness.The services life is 1.8 time longer than H13 from America.

Fig. 2 Performance Comparation of Slitting Blades Made of Three Different Materials for 1.0mm SPCD material

|

||||||||||||||||||

| OUR ADVANTAGES |

| BRAND PURSUIT, Considering from every angle of each knife, it is GOODKLIFE's endless pursuit to design a tool suitable for the user's working conditions. |  |

|

We have more than 30 years of experience |

| .Shearing smooth, no burr, long service life. Please contact us if you have any questions after receiving the product. We'll be patient and work it out for you. |  |

|

MICRON-LEVEL PRECISION, the ultra-high-precision slitting tools perfectly meet the demanding slitting, avoiding all unfavorable factors such as excessive accumulated errors. |

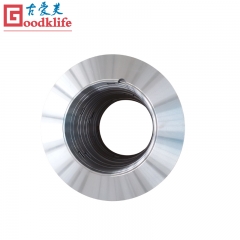

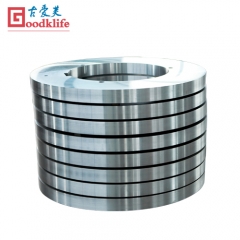

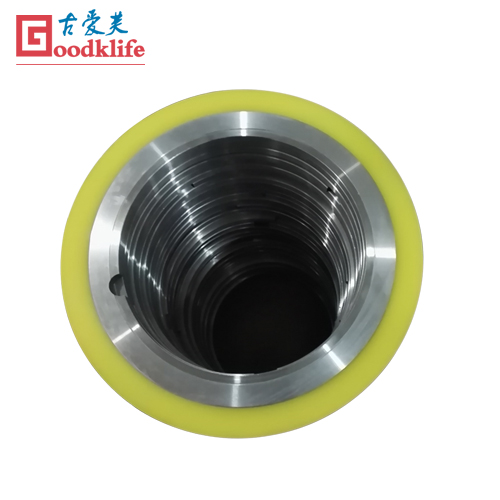

| MORE SLITTING SPARE PARTS FOR SELECTION |

| SPACER | STRIPPER RING | HYDRAULIC NUT |

|

|

|

| PRODUCT | |

| Brand | Goodklife |

| Material | Tool Alloy Steel, Like H13, G1 (refer to Material Recommendation Sheet) |

| Thickness | +/- 0.0010 mm or as request |

| Size | Customized |

| Parallelism | 0.002 mm or as request |

| Flatness | 0.002 mm or as request |

| OD | +/- 0.01 mm or as request |

| ID | H6 or as request |

| Dirt Groove | Yes or as request |

| Keyway | as request |

| Heat treatment | through-hardening |

| Surface Quality | Precision Ground/Lapped/Polished/Mirror Polished |

| CHARACTERISTIC | |

| Specialized for | design for steel coil (such as SPHC、SPHE、Q235、SPCC、SPCD、SPCE , etc) |

| PACKAGING | |

| Inner packaging | applied with anti-rust oil, packed in plastic bag separately or as request |

| Outer packaging | cardboard case/plywood case or as request to be packed solidly suitable for long distance marine transportation and multi-handling and well protected against dampness, moisture, shock, rust and rough handling. We will be liable for any expense and loss attributable to inadequate or improper protective measures taken by us in regard to the packing. |

| Mark & Sign | on the surface of each package the package number, measurement, gross weight , net weight and the wordings "RIGHT SIDE UP"' , "HANDLE WITH CARE", "KEEP DRY", and the above shipping mark will be stenciled with fadeless paint. |

| DOCUMENTS & CERTIFICATE | |

| Commercial Documents | commercial invoice/packing list/insurance policy/certificate of origin/full set of bill of lading |

| Quality Certificates | inspection certificate/raw material data sheet/quality certificate/heat treatment certificate/certificate of quality/certificate of quantity |

| Inspection Report by the third party | SGS/TUV/SAG or as request |

| PAYMENT TERMS | |

| Official Payment | letter of credit (L/C)/payment against documents/TT or as request |

| Quick Payment | western union/credit card/Paypal/alipay/wechat or as request |

| DELIVERY TERMS | |

| Special Service (DDP/DDU) | door to door (by courier/by sea/ by air/by train/by bus or combined transportation) our experienced transportation team provides door to door service, including customs clearance in destination country. |

| Standard Service | FOB/CFR/CIF/FCA or as request |

Maybe you like

Review