Loose Stripper Ring

Professional Design

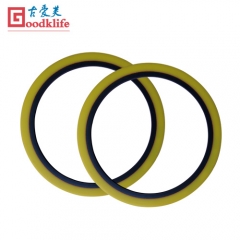

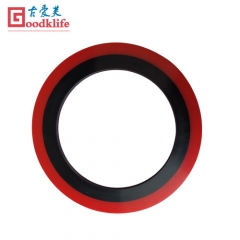

Special Polyurethane, Perbunan/Buna N

Long Lasting Flexibility

Bur-free Slitting

Special Polyurethane, Perbunan/Buna N

Long Lasting Flexibility

Bur-free Slitting

Description

PRODUCTS DESCRIPTION |

|

|

|

|

Logo

Goodklife Logo, Quality Assurance Customized Logo

|

Dual Durometer Dual Durometer Design Longer Work Life |

Marks

Material Code Production Tracking Code |

| PRODUCT PARAMETER | |

| Brand |

Goodklife |

|

Material |

Polyurethane, Perbunan/Buna N |

|

Size |

Customized |

|

Inner Layer |

Harder Hardness |

|

Outer Layer |

Suitable Hardness according to your application |

|

Color |

as request, multiple choices |

|

|

OUTSTANDING PERFORMANCES |

|

Depending on your budget and requirements, our team of experts will develop a customized solution for you, including but not limited to the selection of slitting tool materials, accuracy, etc. If necessary, our field team will come to your company to study the current cutting problems and improve your cutting quality.

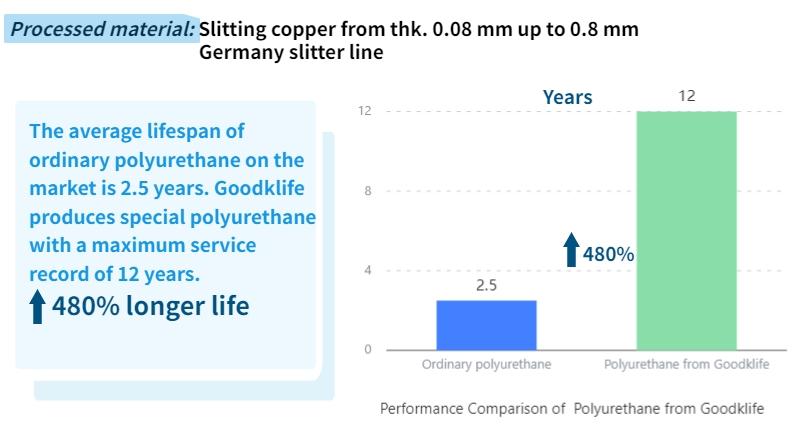

INCREASED LIFESPAN & COST SAVINGSBy selecting the right raw material for the loose stripper ring and combining it with proven production processes, we can produce bonded stripper rings that will last significantly longer and thus reduce your tool purchase costs.

|

PRECISE STRIP WIDTH CONTROLUltra-high precision slitting tools help you achieve perfect strip width control. The application of "+", "0" and "-" marks further improves the cutting accuracy.

|

| width of the 2nd strip 27.95 mm | width of the 6th strip 27.95 mm | width of the 9th strip 27.95 mm |

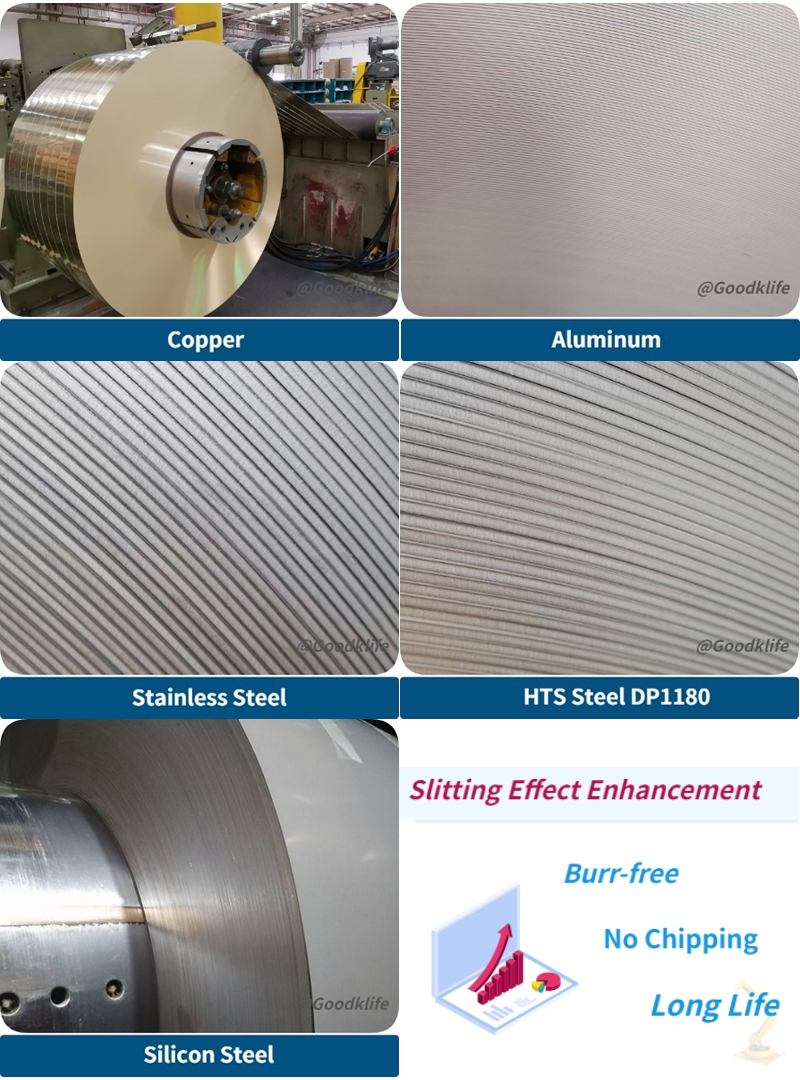

EDGE QUALITY CONTROLSuitable raw materials for tools and advanced production processes ensure robust slitting tools. Ultra-high precision slitting tooling ensures dynamic and stable upper and lower knives clearance.

|

QUALITY ASSURANCE |

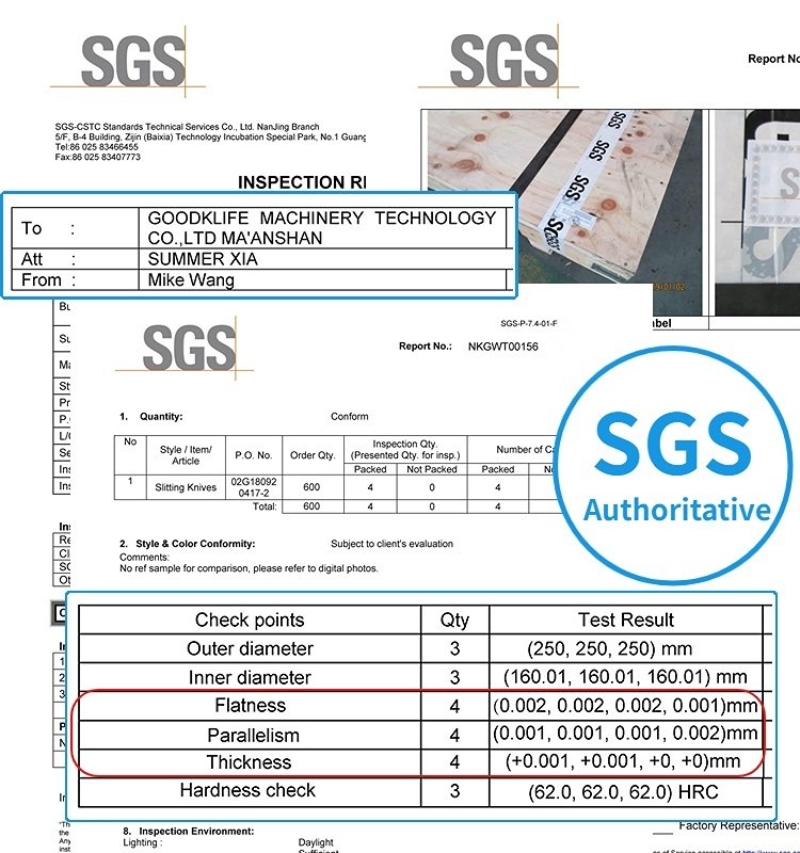

SGS AUTHORITATIVE TESTINGGoodklife has always been committed to providing high-quality, ultra-high-precision cutting tools to customers around the world. In order to enhance mutual trust, for the first cooperation, we now provide free SGS testing services to invited customers to dispel all your doubts. |

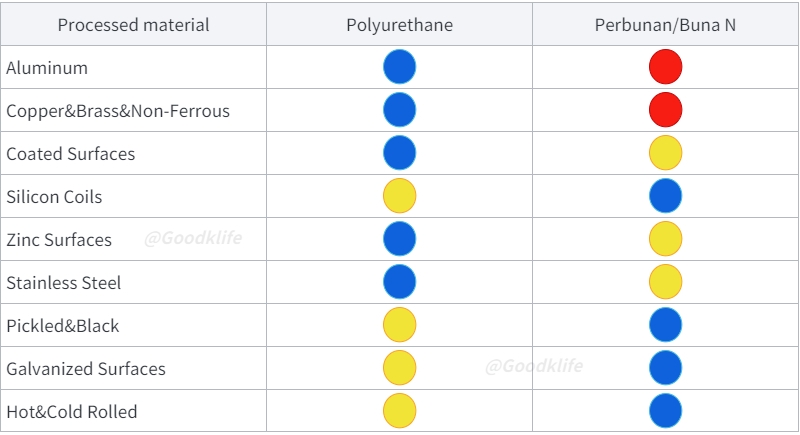

MATERIAL QUALITY ASSURANCERaw material is the foundation of loose stripper rings quality. Goodklife will choose according to the characteristics of the material slit by the customer. Once the rubber material is determined, a suitable range of hardness is also advised based on the thickness and strength of the slit material to ensure perfect cutting results. |

HEAT TREATMENT ASSURANCEGoodklife's heat treatment workshop is fully equipped with various heating, annealing, quenching and tempering equipment, and is equipped with a number of experienced professional senior engineers. After years of experience summarization, the company's unique heat treatment process has been formed. Tools with a thickness of less than 100 mm can be fully hardened into the core, which can ensure that the performance of the blade is the same until it is ground to the min. size. Not only the safety factor of the blade is high, but also the production efficiency can be significantly improved and the cutting cost can be reduced. |

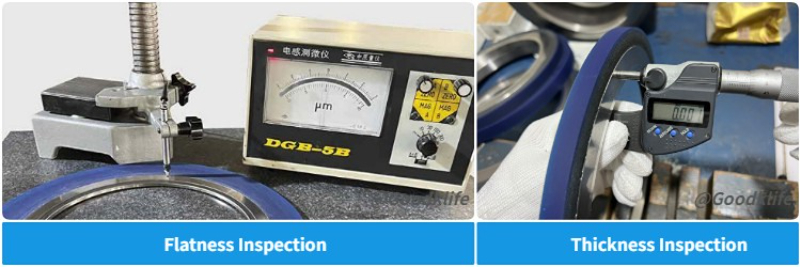

PRECISION TOLERANCE ASSURANCEGoodklife ultra-high precision slitting knives are more like works of art. The company currently has a number of ultra fine grinding machines and lapping machines. Every employee in the finishing workshop is deeply rooted in the pursuit of high precision, and strictly abides by the operating system to ensure that every slitting tool is qualified. |

GOODKLIFE BRAND STORY |

GOODKLIFE - THE CHOICE OF PROFESSIONAL QUALITY

COMPANY PROFILE |

||

GOODKLIFE HISTORY1988 As one of the first companies producing metal shear processing tools in China, we have been continuously exploring high quality products.

2006 Successfully developed a new tool high-strength steel G1, which greatly improved the service life of metalworking tools. The material was awarded the national new invention patent in 2008. 2011 We started to enter the international market, and now our products are selling well in many countries

|

HIGH PRECISION TOLERANCE1998 Started production of slitting tools with a thickness accuracy of +/-0.005 mm.2000 Started mass production of slitting tools with a thickness accuracy of +/-0.005 mm. 2003 Started mass production of slitting tools with a thickness of +/-0.003 mm. 2016 We started mass production of slitting tools with thickness +/-0.001 mm and parallelism and flatness 0.002 mm accuracy. |

|

|

Maybe you like

Dafis kemal Aba fira

Jul 04, 2023

Dafis kemal Aba fira 1000 4142 80785 birr

Dafis kemal Aba fira

Jul 04, 2023

Dafis kemal Aba fira 1000 4142 80785 birr

1

Review