Slitter Knife for HTS&UHTS Steel

Views : 2021

Author : Mr. Jiang

Update time : 2021-12-01 17:02:38

At present, the lightweight and high-strength automobile body structure, as well as reducing energy consumption, reducing emissions, and improving occupant safety have become the mainstream direction of the development of the automobile industry. The automotive industry’s demand for ultra-high-strength automotive steel is increasing year by year. The field of ultra-high-strength steel has become the scientific research focus of major steel companies. The ability to stably provide advanced ultra-high-strength steel products above 1200 MPa has become an important indicator of the level of R&D and manufacturing of steel enterprises. At the same time, the cutting problem has become increasingly prominent. Traditional slitting and cross-cutting tools cannot meet the cutting needs of high-strength steel and ultra-high-strength steel, which are characterized by easy chipping, dullness of the knife edge, and short cutting life. The G1 material jointly developed by Goodklife and several university professors of materials can meet the shearing requirements of high-strength steel and ultra-high-strength steel, and greatly improve the service life of the blade.

♦HIGH-STRENGTH STEEL AND ULTRA-HIGH-STRENGTH STEEL♦

♦HIGH-STRENGTH STEEL AND ULTRA-HIGH-STRENGTH STEEL♦

Some Grades And Their Performance

| Grade | Yield Strength MPa | Tensile Strength MPa | Thickness Range mm |

| 450DP | 250~320 | 450 | 0.5~2.3 |

| 590DP | 340~440 | 590 | 0.5~2.3 |

| 780DP | 420~550 | 780 | 0.7~2.1 |

| 980DP | 550~730 | 980 | 0.8~2.1 |

| 1180DP | 820~1130 | 1180 | 1.0~2.1 |

| 590TR | 380~480 | 590 | 0.7~2.3 |

| 690TR | 400~520 | 690 | 0.7~2.3 |

| 780TR | 420~580 | 780 | 0.7~2.1 |

| 980TR | 450~700 | 980 | 0.9~2.1 |

| 780MS | 500~700 | 780 | 1.0~2.1 |

| 980MS | 700~960 | 980 | 1.0~2.1 |

| 1180MS | 950~1200 | 1180 | 1.0~2.1 |

| 1300MS | 1030~1300 | 1300 | 1.0~2.1 |

| 1500MS | 1200~1500 | 1500 | 1.0~2.1 |

Main Application

High-strength steel and ultra-high-strength steel can be applied to front bumper reinforcements, energy-absorbing boxes, front longitudinal beams, shock-absorbing suspension roofs, dashboard frames, A-pillar reinforcement, door anti-collision beams, door sill reinforcement, and B-pillar reinforcement Panels, middle aisle reinforcements, roof rails, floor cross members, C-pillar reinforcements, rear side rails, rear bumper reinforcements, seat slide rails, seat support panels, seat headrest frames, and seat back edges Board and other parts.

♦SPECIAL SLITTER BLADES FOR HIGH-STRENGTH STEEL AND ULTRA-HIGH-STRENGTH STEEL♦

High-strength steel and ultra-high-strength steel can be applied to front bumper reinforcements, energy-absorbing boxes, front longitudinal beams, shock-absorbing suspension roofs, dashboard frames, A-pillar reinforcement, door anti-collision beams, door sill reinforcement, and B-pillar reinforcement Panels, middle aisle reinforcements, roof rails, floor cross members, C-pillar reinforcements, rear side rails, rear bumper reinforcements, seat slide rails, seat support panels, seat headrest frames, and seat back edges Board and other parts.

♦SPECIAL SLITTER BLADES FOR HIGH-STRENGTH STEEL AND ULTRA-HIGH-STRENGTH STEEL♦

Cutting Difficulties

1. High strength, tensile strength above 440 MPa, some of them can reach 980 MPa, 1180 MPa and 1500 MPa

2. Continuous shear is prone to cracking

3. The blade wears quickly, frequent tool change and grinding, and high production cost

Blade Material Selection

Traditional material D2 (Cr12Mo1V1, 1.2379, SKD11), H13, etc.

D2 is a high-carbon and high-chromium alloy tool steel with good wear resistance and can meet the shearing requirements of thin plates with strength below DP1180. However, its toughness is poor, and it is prone to cracking problems in shearing thicker high-strength steels.

Due to its limited strength, H13 wears quickly when cutting high-strength steel and ultra-high-strength steel, and has a short service life. It is prone to problems such as dullness of the knife edge, resulting in excessive burrs on the edge of the strips.

New Material G1 is a patented material of Goodklife Company, which belongs to low-carbon high-alloy special steel, specially designed for (ultra) high-strength steel. Compared with traditional blade materials, its cutting life is significantly improved.

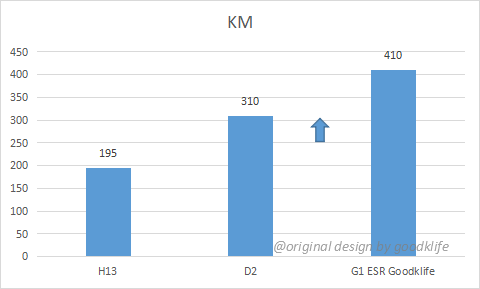

Figure 1 shows the statistical data of shearing volume when one automotive sheet company uses our company's slitter blades made of three different materials to cut DP780 with 1.8 mm thickness.

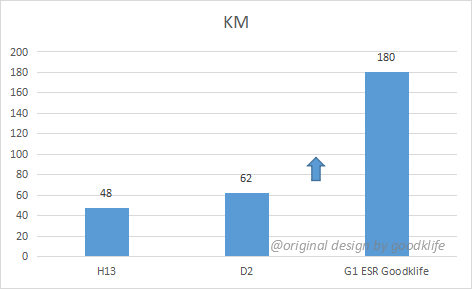

Figure 2 shows the statistical data of shearing volume when one automotive sheet company uses our company's slitter blades made of three different materials to cut DP1180 with 2.0 mm thickness.

Fig. 1 Performance Comparation of Slitter Knives Made of Three Different Materials for Slitting DP780 with 1.8 mm Thickness

Fig.2 Performance Comparation of Slitter Knives Made of Three Different Materials for Slitting DP1180 with 2 mm Thickness

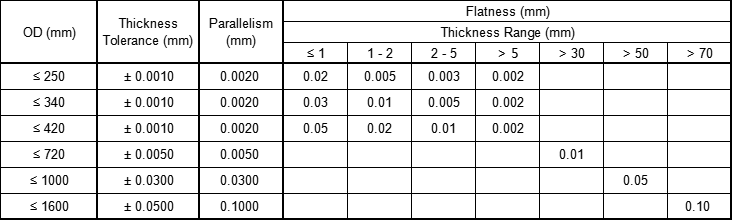

Blade Accuracy Selection

External tolerance: +/- 0.01 - +/- 0.02 mm

Inner diameter tolerance: H6, H7

Surface finish: Ra=0.2, 0.4 μm

See Table 1 for thickness, flatness and parallelism

Table 1 Precision for Slitter Blades from Goodklife

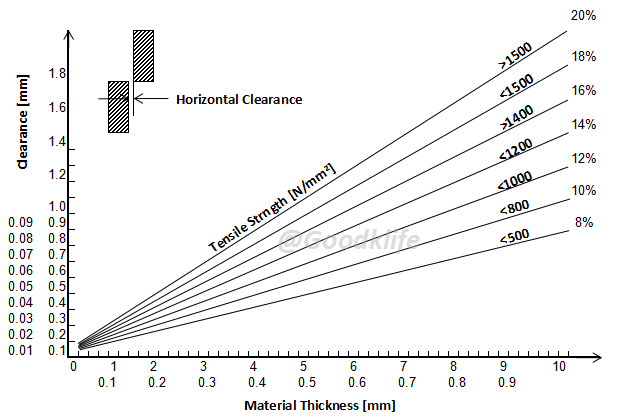

Horizontal Gap (Clearance) Selection

Accurate and constant horizontal slitter knife clearance is a decisive factor to ensure perfect cutting, but it is affected by many factors, including but not limited to slitting line accuracy, bearing accuracy, cutter shaft accuracy, and slitting tool accuracy. In addition, choosing the right horizontal clearance is also very important. Figure 3 is the horizontal clearance diagram for slitting (ultra) high-strength steel. Processing companies can use this as a reference and make adjustments according to the shearing effect, and finally find the most perfect horizontal clearance value.

Fig. 3 Horizontal Clearance Diagram for Slitting (Ultra) High-Strength Steel

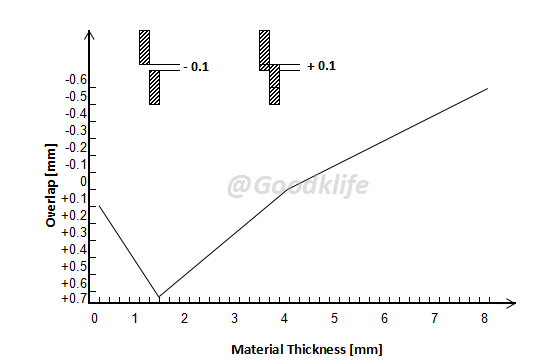

Overlap (Penetration) Selection

We know that during the slitting process, the overlap of the upper and lower blades needs to be adjusted according to the performance and thickness of the coil. Excessive overlap will cause repeated shearing problems, which will not only cause excessive burrs on the edge of the strips, but also accelerate the wear of the slitting blade. Due to the high strength of (ultra) high-strength steel, as long as the upper and lower knives overlap too much, the wear rate of the blades will be more obvious. Figure 4 is a overlap graph for slitting (ultra) high-strength steel, which can be adjusted by the producer according to the actual situation. There is only one general principle, as long as the overlap amount can satisfy that all strips can be completely cut, the smaller the better.

Fig. 4 Overlap Graph for Slitting (Ultra) High-Strength Steel

***RELATED ARTICLES RECOMMENDED***

***(ULTRA) HIGH-STRENGTH STEEL SLITTING LINE MANUFACTURER RECOMMENDED***

***(ULTRA) HIGH-STRENGTH STEEL SLITTING LINE MANUFACTURER RECOMMENDED***