How to choose the surface roughness of slitting knives and related tools?

Views : 3563

Author : Xiangrong Yuan

Update time : 2009-02-03 14:25:00

The surface roughness of the knife has a great relationship with the sharpness of the cutting edge, because the cutting edge of a slitting knife is composed of the out diameter and two sidefaces of the knife. If the out diameter and two sidefaces of the knife are rough, then the cutting edge formed by them becomes something like a saw blade, which will seriously affect the cutting quality of the knife and its lifetime.

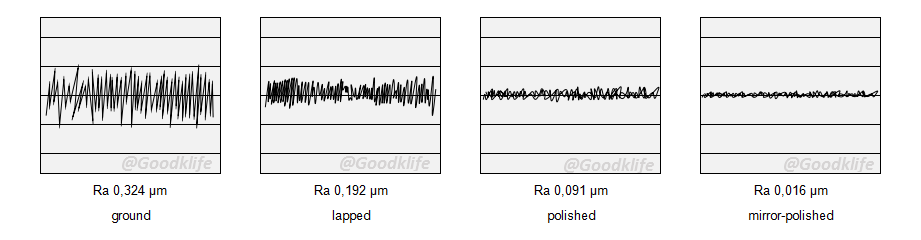

For the surface roughness of precision SLITTING KNIVES, BONDED STRIPPER RINGS, and SPACERS, the general requirement is Ra = 0.2μm, but for special needs, the polishing method can be used to reach Ra =0.1μm, even 0.05μm. Different machining processes can result in different surface finishes (Figure 1).

For the surface roughness of precision SLITTING KNIVES, BONDED STRIPPER RINGS, and SPACERS, the general requirement is Ra = 0.2μm, but for special needs, the polishing method can be used to reach Ra =0.1μm, even 0.05μm. Different machining processes can result in different surface finishes (Figure 1).

Figure 1 Surface Quality of Slitter Blades with Different Processing from Goodklife