Slitter Knife for Ultra-precision Silicon Coil Slitting - Goodklife TECH

Views : 1011

Author : Summer Xia

Update time : 2023-07-21 20:55:21

In order to achieve high-quality silicon strips, the following elements must be combined:

♦Advanced equipment

♦Advanced equipment

♦High-quality slitting tools

♦High-quality slitting tools

♦Experienced Operators

♦Experienced Operators

The role of the slitting tool as a consumable in the entire slitting process is very important, and its quality directly affects the slitting quality of the silicon strip. High-quality slitting tools must have high precision and long-lasting sharpness, so that the gap and overlap between the upper and lower blades can be maintained at all times. Since 1988, Goodklife Machinery Technology has continuously iterated its production technology, and currently the precision and sharpness of all knives are at the world's advanced level.

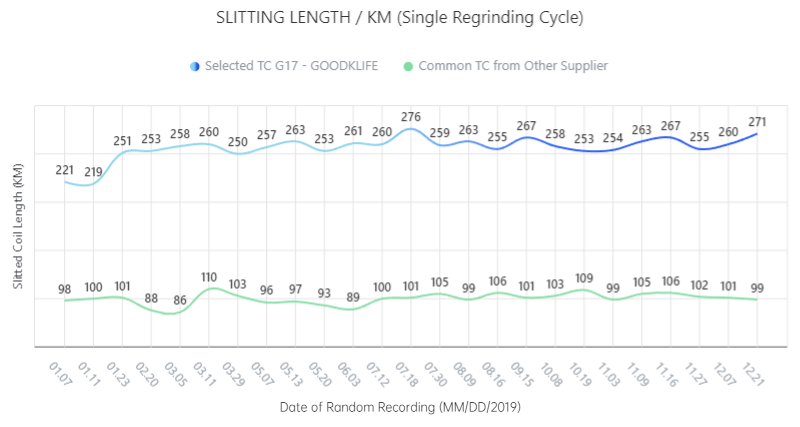

Special TC Material - G17

Silicon steel slitting, especially oriented silicon steel slitting has been facing problems such as fast knife wear and large strip burrs, etc. Goodklife has been deeply engaged in silicon steel slitting for 30 years and has jointly developed the G17 carbide material. Under the premise of ensuring that the knife does not chip, greatly improve the service life of the knife. The following is the detailed data of the utilization record of a customer of our company.

* Case Study: Tungsten Carbide Slitting Knives

* Client: Beijing

* Slitting Line Manufacturer: GEORG

* Processed Material: CRGO 0.18 - 0.3 mm.

* Knife Manufacturer: GOODKLIFE V.S.

GOODKLIFE V.S.  SUPPLIER from JAPAN

SUPPLIER from JAPAN

* Case Study: Tungsten Carbide Slitting Knives

* Client: Beijing

* Slitting Line Manufacturer: GEORG

* Processed Material: CRGO 0.18 - 0.3 mm.

* Knife Manufacturer:

Comparison Chart of Single Regrinding Shear Kilometers

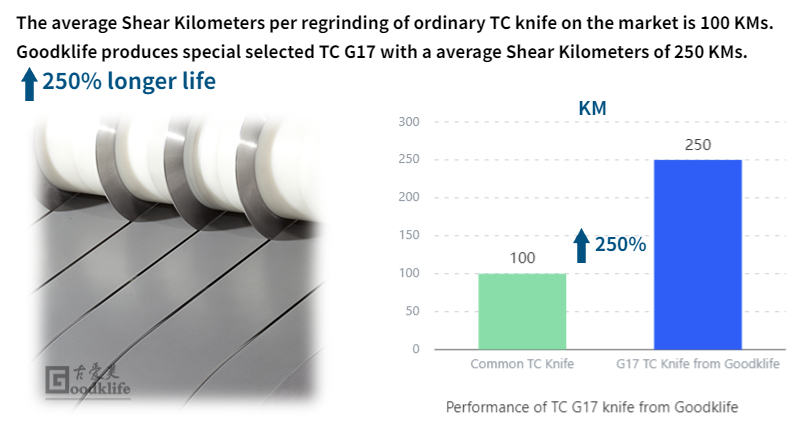

Feedback from Client in Beijing: The above chart shows that Goodklife's special TC G17 slitter knives have an average shear capacity of 250 KMs or more in a single resharpening, while TC slitter knives on the market just have an average shear capacity of about 100 KMs in a single resharpening. The slitting performance of Goodklife's G17 knives is increased by 250%.

GOODKLIFE G18 Material Knife Life Improvement Chart

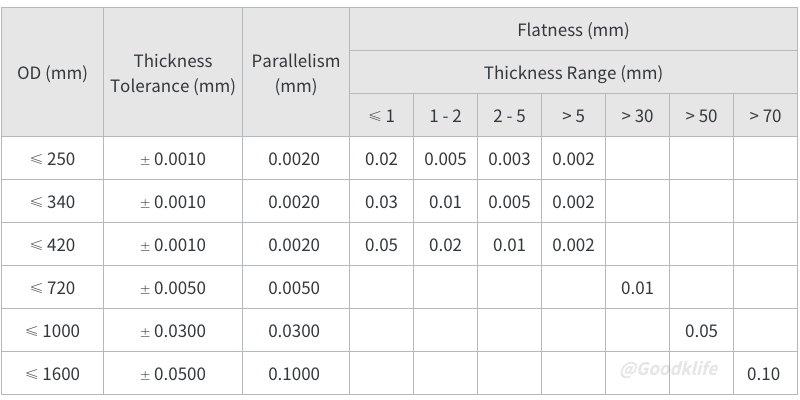

Ultra-precise Tolerance

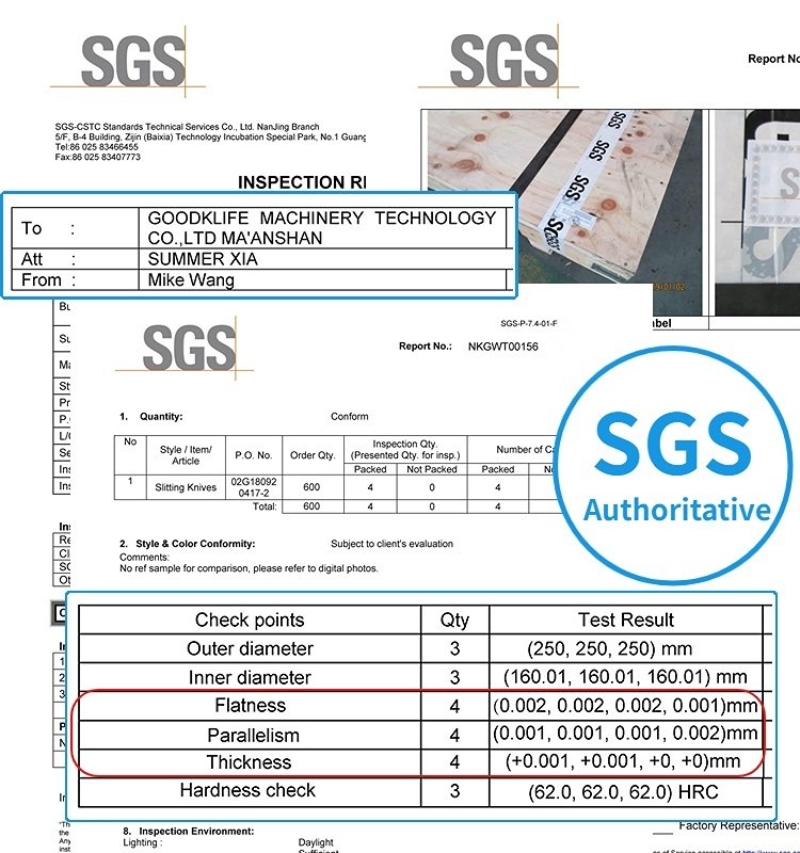

Sufficiently high flatness and parallelism are necessary conditions to ensure that the shear clearance between the upper and lower slitter blades of the slitting machine is always consistent during dynamic operation. Correct clearance is at the heart of ensuring precision cutting. Goodklife has 15 state-of-the-art lapping machines, combined with a well-established production process, to ensure the quality of each piece of tooling.

Goodklife Slitter Tooling Tolerance

SGS Authoritative Inspection - Precision Assurance

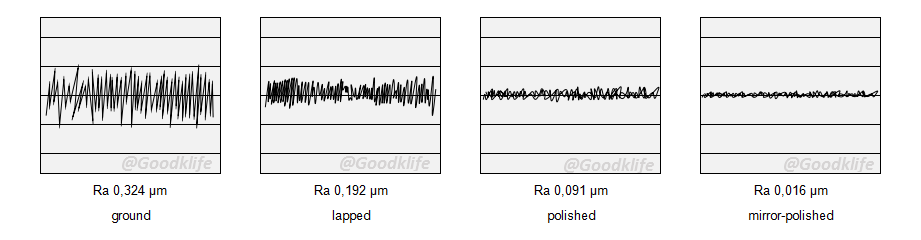

A good surface roughness of the blade surface can improve the rigidity of the entire shearing system, increase the sharpness of the blade, reduce micro cracks on the blade and prolong the life of the blade. Different machining processes can result in different surface finishes. For high-precision silicon coil processing, it is generally necessary to choose 0.1 - 0.2 μm.

Surface Quality of Slitter Blades with Different Processing from Goodklife

PRODUCTS DESCRIPTION |