How to choose the overlap (penetration) between the upper and lower knives for slitting metal coils? -- GOODKLIFE TECH

Views : 5393

Author : Mr. Jiang

Update time : 2023-04-14 19:42:03

In the previous article, we analyzed the importance of the horizontal clearance of the upper and lower blades for slitting quality and how to choose the right clearance. In addition to the horizontal clearance, the setting of the overlap (penetration) between the upper and lower blades is also one of the most important issues in metal slitting, which not only affects the quality of the strips but also the service life of the blades.

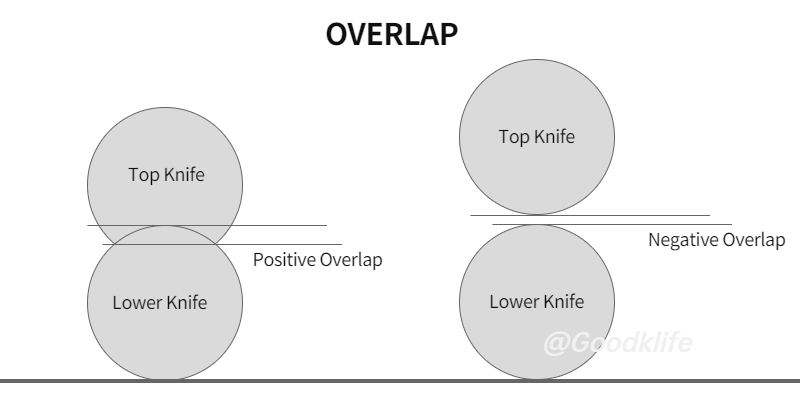

First of all, let's look at what is the overlap. Cutting any product requires a "cutting point", to meet this "cutting point", the upper and lower blades need to have a certain amount of overlap. As shown in Figure 1, the actual value of the overlap is the distance of the upper blade into the lower blade.

First of all, let's look at what is the overlap. Cutting any product requires a "cutting point", to meet this "cutting point", the upper and lower blades need to have a certain amount of overlap. As shown in Figure 1, the actual value of the overlap is the distance of the upper blade into the lower blade.

Figure 1 Schematic Diagram of the Overlap of the Upper and Lower Circular Knives for Metal Slitting

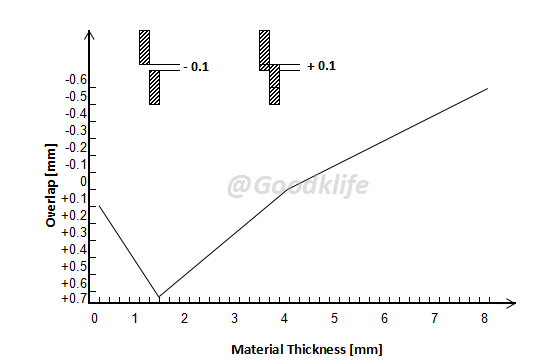

When cutting thin coils, the upper and lower blades must have a certain amount of overlap in order to complete the shear, and for cutting thicker materials, the overlap of the blades is sometimes negative. In this case, the upper and lower blades do not overlap, but leave a certain gap. There is no exact formula for calculating the overlap of the upper and lower blades, and they are all given empirically derived reference values. Different materials, thicknesses, tool quality, slitting lines and many other factors will have an impact on it. Figure 2 shows the relationship between the thickness of ordinary carbon steel and the amount of blades overlap. Coil thickness below 1.2mm, the overlap is proportional to the thickness of the coil, and when the thickness is greater than 1.2mm, the relationship is inversely proportional. When the coil thickness comes to 4mm or more, the upper and lower blades will no longer overlap. Figure 2 is only the relationship curve between the overlap and coil thickness when slitting ordinary carbon steel. The graphs for other materials will be different, but the general direction is similar.

Figure 2 the Relationship Between the Thickness of Ordinary Carbon Steel and the Amount of Blades Overlap

In the actual production process, we need to continue to explore the actual situation to find the most appropriate overlap data curve. There is a golden rule regarding the setting of the overlap amount, the smaller the overlap the better, provided that the complete cut is satisfied. This min. overlap amount can be found by several trial cuts. However, due to the slow speed during trial cutting, the speed of formal slitting is often much faster, and if the data obtained during trial cutting is used completely it will produce a situation where the middle strips is not cut completely. To avoid this, the overlap during formal slitting should be slightly larger than the data obtained during test cutting. For more technical questions about metal slitting, please feel free to contact us.