Slitter Knife for Ultra-precision Aluminum Slitting - Goodklife TECH

Views : 1822

Author : Mr. Jiang

Update time : 2022-08-24 17:10:26

In order to achieve high-quality aluminum strips, the following elements must be combined:

Advanced equipment

Advanced equipment

High-quality slitting tools

High-quality slitting tools

Experienced Operators

Experienced Operators

Material Selection

Material for Slitter Knife

Material for Spacer

Material for Stripper Ring

Software GSAP support (Goodklife Slitting Assembling Program)

The computer software GSAP specially designed by Goodklife can consciously select "0", "+", "-" tools, and tell the operators the quantity they need, and the operators can directly assemble slitting tools according to the software outputs. The efficiency and precision of slitting tools assembling can be greatly improved. With the help of this software, the clearance accuracy of the knives can be greatly improved, the inventory of the knives can be reduced, the time of slitting tools assembling can be shortened, and the utilization rate of coils can be improved, which is very beneficial to the management of production and tools.

Selection of knife clearance

The clearance of the blade has a very close relationship with the thickness and strength of the material to be sheared Moreover, in the process of shearing, the material to be sheared is not 100% sheared, but part of the thickness is sheared and part is pulled off.

Determination of the overlapping of the upper and lower blades

It can be seen from Figure 3 that the overlap is the largest when the thickness of the processed material is 1.2 mm. When the thickness is below 1.2 mm, the overlap increases with the thickness; when it exceeds 1.2 mm, the overlap decreases with the thickness.

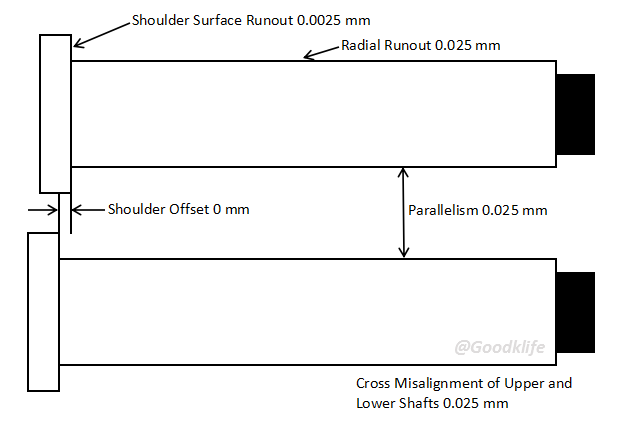

Parallelism accuracy of slitting arbors

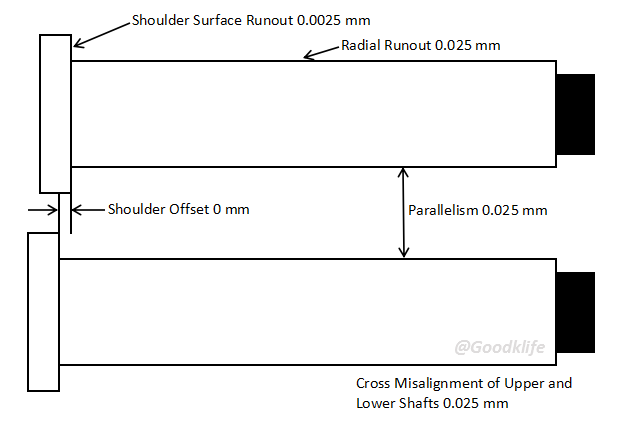

Machine precision and blade precision are the two most fundamental elements to ensure precision cutting. After the machine has been running for a period of time, each sheet metal processing enterprise is required to keep abreast of whether its accuracy has changed. Figure 4 shows the parallelism accuracy requirements of the upper and lower arbors of the slitting machine

The role of the slitting tool as a consumable in the entire slitting process is very important, and its quality directly affects the slitting quality of the aluminum strip. High-quality slitting tools must have high precision and long-lasting sharpness, so that the gap and overlap between the upper and lower blades can be maintained at all times. Since 1988, the Goodklife Machinery Technology has continuously iterated its production technology, and currently the precision and sharpness of all knives are at the world's advanced level. In this article, we will introduce Goodklife high-precision aluminum strip slitting tool from the aspects of material selection, precision and use specifications.

Material Selection

Material for Slitter Knife

According to the thickness range and the strength of the aluminum coil, the most suitable knife raw material is selected. In order to achieve the most ideal slitting effect, the customer should inform the detailed work conditions. Generally speaking, when cutting thicker aluminum coils, the knife needs to choose a material with sufficient toughness to avoid the problem of chipping during use. When cutting thin plates, the knife is more inclined to choose a material with better wear resistance, thereby improving the work life.

Table 1 is the recommended material for Goodklife Slitter Knife for Ultra-precision Aluminum Slitting (G is the material code of Goodklife Machinery Technology)

Table 1 is the recommended material for Goodklife Slitter Knife for Ultra-precision Aluminum Slitting (G is the material code of Goodklife Machinery Technology)

Table 1 The Recommended Material For Goodklife Slitter Knife For Ultra-Precision Aluminum Slitting

| Thickness Range | < 1,2 | 1,2 - 2,0 | 2,0 - 4,0 | > 4,0 |

| Material Selection | G24, G6 | G6, G8 | G8, G1 | G1, G2 |

Material for Spacer

The material of spacer for the high-precision aluminum coil slitting machine is usually made of alloy tool steel instead of carbon steel. The spacer made of alloy tool steel has higher hardness and durability, which is conducive to maintaining the rigidity of the entire shearing system. But it also has its own shortcomings. It is easy to rust. If it is a coastal city, the rusting phenomenon is more prominent. For high-precision slitting, once the tool is rusted, it cannot be used. If the rust is large and it is on the surface of the spacer ring, even if it is manually erased, it will have a greater impact on its accuracy. Faced with this situation, we can choose stainless steel. The special stainless steel spacer ring from Goodklife will not rust after many years of use, and can maintain high hardness at the same time.

Material for Stripper Ring

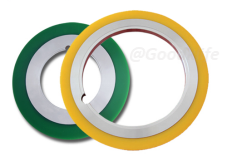

The stripper ring is divided into two types: bonded stripper ring and loose stripper ring, as shown in Figure 1.

For high-precision aluminum coil slitting, we recommend always using bonded stripper rings, so that the entire shearing quality can be controlled. The bonded stripper ring is composed of two parts, the inner metal part and the outer rubber part. The material selection standard of the metal part is the same as that of the spacer ring introduced above. Alloy tool steel or special stainless steel can be selected. The outer rubber part is made of high-strength polyurethane.

For high-precision aluminum coil slitting, we recommend always using bonded stripper rings, so that the entire shearing quality can be controlled. The bonded stripper ring is composed of two parts, the inner metal part and the outer rubber part. The material selection standard of the metal part is the same as that of the spacer ring introduced above. Alloy tool steel or special stainless steel can be selected. The outer rubber part is made of high-strength polyurethane.

|

|

Figure 1 Bonded Stripper Ring (Left) and Loose Stripper Ring (Right)

Tolerance Selection

Flatness and Parallelism

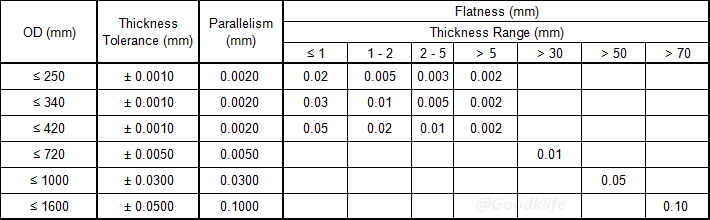

Sufficiently high flatness and parallelism are necessary conditions to ensure that the shear clearance between the upper and lower slitter blades of the slitting machine is always consistent during dynamic operation. Correct clearance is at the heart of ensuring precision cutting. If the surfaces of circular knives are not flat, or the two sides of the blade are not parallel, the gap between the upper and lower blades is always changing. In addition, the reaction force generated by the extrusion of the strip during slitting also causes the gap to change continuously. This will make it impossible to get burr-free strips. For example, to slit aluminum coils with a thickness of 0.07 mm, the gap requirement is 5 μm, but if the flatness and parallelism of the blade face are within 5 μm (this is quite high precision in the machining industry), then the gap error will be as high as 50%. As for the problems that burrs will bring to the processing and quality of downstream products, this article will not repeat them.

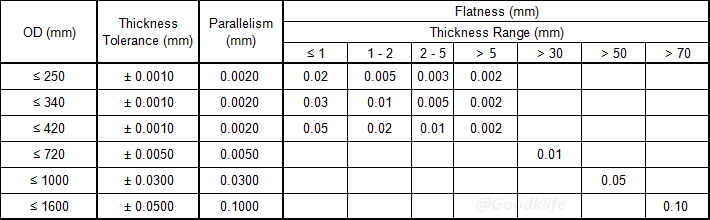

Knife thickness tolerance

The thickness tolerance of the blade is mainly to ensure the cutting accuracy of the width of the metal strip and prevent the cumulative error in the knife assembly. If a blade with a thickness tolerance of 1~2 μm or even 0.5 μm cannot be provided, the cumulative error when multiple slitting knives are assembled is unavoidable. Refer to Table 2

for the thickness tolerance that the blade should have when precision slitting.

Flatness and Parallelism

Sufficiently high flatness and parallelism are necessary conditions to ensure that the shear clearance between the upper and lower slitter blades of the slitting machine is always consistent during dynamic operation. Correct clearance is at the heart of ensuring precision cutting. If the surfaces of circular knives are not flat, or the two sides of the blade are not parallel, the gap between the upper and lower blades is always changing. In addition, the reaction force generated by the extrusion of the strip during slitting also causes the gap to change continuously. This will make it impossible to get burr-free strips. For example, to slit aluminum coils with a thickness of 0.07 mm, the gap requirement is 5 μm, but if the flatness and parallelism of the blade face are within 5 μm (this is quite high precision in the machining industry), then the gap error will be as high as 50%. As for the problems that burrs will bring to the processing and quality of downstream products, this article will not repeat them.

Knife thickness tolerance

The thickness tolerance of the blade is mainly to ensure the cutting accuracy of the width of the metal strip and prevent the cumulative error in the knife assembly. If a blade with a thickness tolerance of 1~2 μm or even 0.5 μm cannot be provided, the cumulative error when multiple slitting knives are assembled is unavoidable. Refer to Table 2

for the thickness tolerance that the blade should have when precision slitting.

Table 2 Goodklife Circular Knife Tolerance

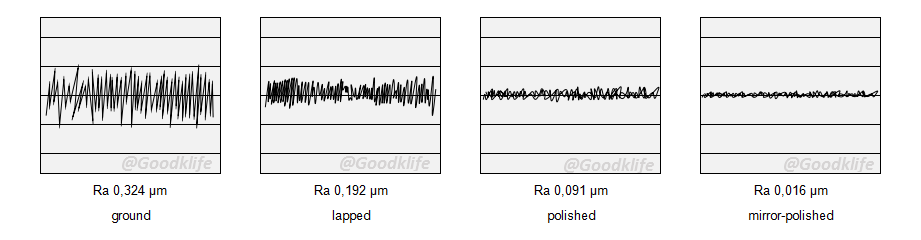

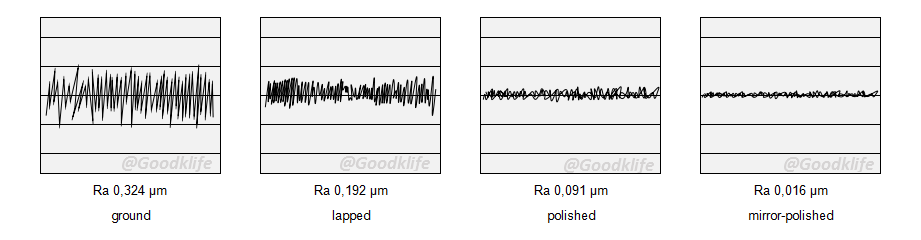

A good surface roughness of the blade surface can improve the rigidity of the entire shearing system, increase the sharpness of the blade, reduce micro cracks on the blade and prolong the life of the blade. Different machining processes can result in different surface finishes (Figure 2). For high-precision aluminum coil processing, it is generally necessary to choose 0.05 - 0.1 μm.

Figure 2 Surface Quality of Slitter Blades with Different Processing from Goodklife

Inner circle tolerance

The inner circle tolerance of the blade and rubber ring should be controlled within H6 and H7 to reduce their radial runout. In order to adapt to the cutting of thin materials (such as 0.05 mm material), the radial runout will be more strictly controlled, and they must use expansion shafts. At this time, the inner circle tolerance should be controlled within 0.01 mm.

The inner circle tolerance of the blade and rubber ring should be controlled within H6 and H7 to reduce their radial runout. In order to adapt to the cutting of thin materials (such as 0.05 mm material), the radial runout will be more strictly controlled, and they must use expansion shafts. At this time, the inner circle tolerance should be controlled within 0.01 mm.

| Accuracy Guaranteed: All tool accuracy is guaranteed to be correct. In case of discrepancies, customers can choose unconditional refund or re-production for free. However this will never happen. |

Correct use of tools and spacers

After you have a good machine and blade, you should also use the knife and assembling knife correctly.

Slitter Tool Accuracy Reclassification

The re-grouping of precision blades can greatly improve the precision of blade assembling and eliminate accumulated errors. Since it is impossible for a manufacturer to produce blades of absolutely the same thickness, there is always some allowable error. And the slitting machine is composed of many basic cutting units, and each unit is composed of many knives, bonded stripper rings and spacers. Even the most precise blades that fully meet the requirements of the drawings will have accumulated errors after tens or hundreds of blades are stacked together. In order to completely eliminate the accumulated error, the user must group the blades so as to improve the accuracy of the blade assembly. A knife with poor precision cannot use software because no one knows its actual size value. The grouping is to divide all blades and rubber bonded stripper rings, spacers with a tolerance within +/- 1 μm into three groups according to their thickness tolerances -1 μm to -0.3 μm, -0.3 μm to 0.3 μm, 0.3 μm to 1 μm, respectively Marked with "-", "0", "+" marks. When assembling tools, use the principle of "+" and "-" to offset, and put tools (slitter knives, bonded stripper rings and spacers) with zero total error together as much as possible, thereby reducing the gap error of each unit and the total accumulated error. Figure 3 shows the slitting tools marked with "+", "0" and "-" produced by Goodklife Machinery Technology.

After you have a good machine and blade, you should also use the knife and assembling knife correctly.

Slitter Tool Accuracy Reclassification

The re-grouping of precision blades can greatly improve the precision of blade assembling and eliminate accumulated errors. Since it is impossible for a manufacturer to produce blades of absolutely the same thickness, there is always some allowable error. And the slitting machine is composed of many basic cutting units, and each unit is composed of many knives, bonded stripper rings and spacers. Even the most precise blades that fully meet the requirements of the drawings will have accumulated errors after tens or hundreds of blades are stacked together. In order to completely eliminate the accumulated error, the user must group the blades so as to improve the accuracy of the blade assembly. A knife with poor precision cannot use software because no one knows its actual size value. The grouping is to divide all blades and rubber bonded stripper rings, spacers with a tolerance within +/- 1 μm into three groups according to their thickness tolerances -1 μm to -0.3 μm, -0.3 μm to 0.3 μm, 0.3 μm to 1 μm, respectively Marked with "-", "0", "+" marks. When assembling tools, use the principle of "+" and "-" to offset, and put tools (slitter knives, bonded stripper rings and spacers) with zero total error together as much as possible, thereby reducing the gap error of each unit and the total accumulated error. Figure 3 shows the slitting tools marked with "+", "0" and "-" produced by Goodklife Machinery Technology.

Figure 3 Slitting Tools Marked With "+", "0" and "-" Produced by Goodklife

Software GSAP support (Goodklife Slitting Assembling Program)

The computer software GSAP specially designed by Goodklife can consciously select "0", "+", "-" tools, and tell the operators the quantity they need, and the operators can directly assemble slitting tools according to the software outputs. The efficiency and precision of slitting tools assembling can be greatly improved. With the help of this software, the clearance accuracy of the knives can be greatly improved, the inventory of the knives can be reduced, the time of slitting tools assembling can be shortened, and the utilization rate of coils can be improved, which is very beneficial to the management of production and tools.

Selection of knife clearance

The clearance of the blade has a very close relationship with the thickness and strength of the material to be sheared Moreover, in the process of shearing, the material to be sheared is not 100% sheared, but part of the thickness is sheared and part is pulled off.

Determination of the overlapping of the upper and lower blades

It can be seen from Figure 3 that the overlap is the largest when the thickness of the processed material is 1.2 mm. When the thickness is below 1.2 mm, the overlap increases with the thickness; when it exceeds 1.2 mm, the overlap decreases with the thickness.

Parallelism accuracy of slitting arbors

Machine precision and blade precision are the two most fundamental elements to ensure precision cutting. After the machine has been running for a period of time, each sheet metal processing enterprise is required to keep abreast of whether its accuracy has changed. Figure 4 shows the parallelism accuracy requirements of the upper and lower arbors of the slitting machine

Figure 4 Accuracy Requirements of the Upper and Lower Arbors of the Slitting Machine

For more information, you are welcome to contact us anytime. We are also actively looking for broader cooperation. As long as you are a steel mill with a certain scale, a well-known local metal processing or manufacturer, you will have the opportunity to use our sample products for free.