Special Material Refining Progress - ESR

Views : 1635

Author : Summer Xia

Update time : 2022-09-02 12:02:09

When purchasing slitting circular knives, the first thing is to determine the material of the knife. Professional slitter tool manufacturers will inquire in detail about the code, thickness range, tensile strength and other information of the material to be cut, and if necessary, they need to go to the site to understand the specific working conditions. This shows the importance of raw materials to the quality of the knife. Appropriate raw materials can ensure the lasting sharpness of the knife and sufficient toughness to avoid chipping during use.

Knife material is so important that Goodklife has been using the ESR steel-making process since the beginning of this century to further improve the quality of the knife raw material.

ESR - Electroslag Remelting Process

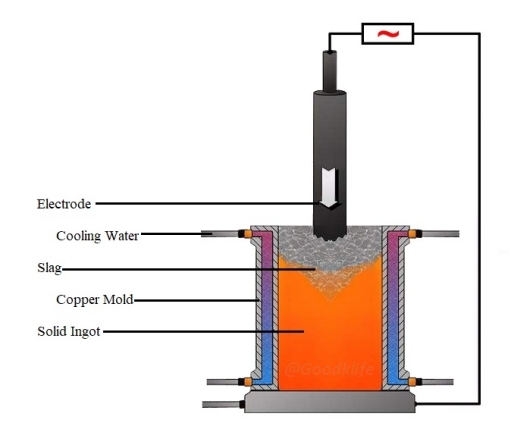

Electroslag remelting steel is a method of smelting using the resistance heat generated when the current passes through the molten slag as a heat source. The basic process of electroslag remelting is shown in Figure 1.

Knife material is so important that Goodklife has been using the ESR steel-making process since the beginning of this century to further improve the quality of the knife raw material.

ESR - Electroslag Remelting Process

Electroslag remelting steel is a method of smelting using the resistance heat generated when the current passes through the molten slag as a heat source. The basic process of electroslag remelting is shown in Figure 1.

Figure 1 The Basic Process of Electroslag Remelting

ESR’s main purpose is to purify the metal and obtain a clean, uniform and dense steel ingot. The steel remelted by electroslag has high purity, low sulfur content, less non-metallic inclusions, smooth ingot surface, clean, uniform and dense, uniform metallographic structure and chemical composition. Figure 2 shows the Microstructure of conventional melted material and ESR remelting material.

|

|

Figure 2 The Microstructure of Conventional Melted Material (Left) and ESR Remelting Material (Right)

|

By the ESR process, the following properties of the material are improved:

√ Improved toughness√ Improved strength √ Improved purity √ Improved creep resistance |

Improvement of Knife’s performance by ESR process

Avoid the chipping problem

For a long time in the past, Goodklife has continuously tracked the performance of knives made from ESR raw materials by several customers. Table 1 is data from a large slitting center in Shanghai, China.

* Tracking Object: Slitting Knife Ø400 x Ø260 x 15 mm

* Tracking Period: 15.03.2017 - 13.03.2018

* Client: Slitting Center in Shanghai, China

* Processed material: HTS below 2.5 mm, DP590, DP780, DP1180 and other HTS

* Maximum tensile strength = 1350 N/mm2

* Blade material:

G1 - ESR, core hardened at 56-59 HRC (HRC 57/58)

G1 - Conventional, core hardened at 56-59 HRC (HRC 57/58)

G1 - Conventional, core hardened at 56-59 HRC (HRC 57/58)

Table 1 Statistical Table of Abnormal Chipping of Knives Made of ESR And Conventional Materials

| Conclusion: Compared with the blades made of traditional process materials, the grinding times of blades made of ESR process materials decreased by 55%, and the times of abnormal chippings decreased by 96.5%. |

Extend the service life

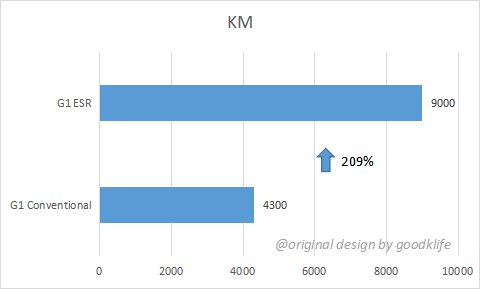

The knife made of ESR raw material can not only avoid the problem of chipping, but also greatly improve the service life. Figure 3 is a comparison chart drawn by Goodklife based on the data recorded in the finishing workshop of Anshan Iron and Steel, which reflects the influence of electroslag remelting raw materials on trimming knife’s life.

* Study Tool: Trimming Knife Ø315 x Ø200 x 40 mm

* Client: Anshan Iron and Steel

* Processed material: CQ, DQ, DDQ, DP, TRIP, 0.3 - 2.5 mm

* Maximum tensile strength = 1750 N/mm2

* Blade material:

* Study Tool: Trimming Knife Ø315 x Ø200 x 40 mm

* Client: Anshan Iron and Steel

* Processed material: CQ, DQ, DDQ, DP, TRIP, 0.3 - 2.5 mm

* Maximum tensile strength = 1750 N/mm2

* Blade material:

G1 - ESR, core hardened at 57-60 HRC (HRC 58/59)

G1 - Conventional, core hardened at 57-60 HRC (HRC 58/59)

Figure 3 Comparison Chart of Tool Life of Conventional Material Knives and ESR Material Knives

| Conclusion: Compared with the blades made of traditional process materials, the service life of blades made of ESR process materials increased by 209%. |

For more information, you are welcome to contact us anytime. We are also actively looking for broader cooperation. As long as you are a steel mill with a certain scale, a well-known local metal processing or manufacturer, you will have the opportunity to use our sample products for free.