How to choose accuracy level for slitting knives and relative tools?

Views : 2803

Author : Mr. Jiang

Update time : 2021-05-14 20:15:32

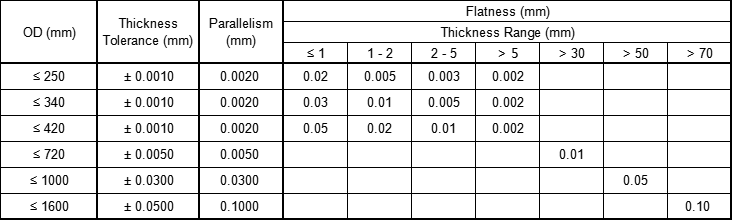

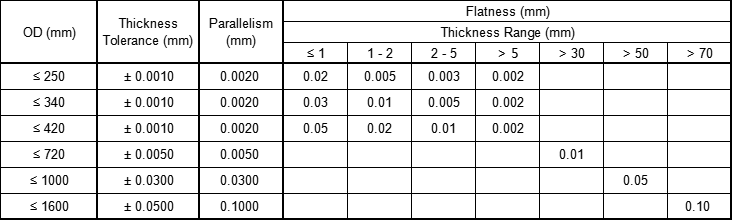

In order to meet the needs of users and the level of its own manufacturing capabilities, the accuracy of the tools on the market is roughly divided into three grades. The worst accuracy is about 0.01 mm (that is, 10 um), followed by about 0.005 mm (that is, 5 um), and the best is about 0.002 mm (that is, 2 um). At present, only a few companies in the world can produce tools with a stable accuracy within 2 um. Table 1 is the accuracy level of the products of Goodklife Company, China.

Table 1 Goodklife Circular Knife Tolerance

Generally speaking, the thicker the tool is, the higher the flatness is. This is because the thin ring is easy to deform during production and use. The thinner the ring is, the more difficult it is to manufacture. However, the unevenness of the thin ring does not affect the accuracy of the installation. As long as the parallelism is good, the thin spacer ring will be flattened under the strong axial pressure of the lock nut or hydraulic nut. But the thick ring is not easy to be flattened, and it is not easy to deform, so the flatness of it is required to be higher.

The higher the precision of the tool, the more expensive the price, so customers should choose different precision tools and knives according to their own needs. If you really want to slit multiple metal strips precisely, you must buy high-precision tools at a high price. But for slitting thick plates, there is no need to choose high-precision tools.