Resource Recycling and Selection of Scrap Shredding Knives

Views : 792

Author : Wallivia

Update time : 2022-03-15 15:17:27

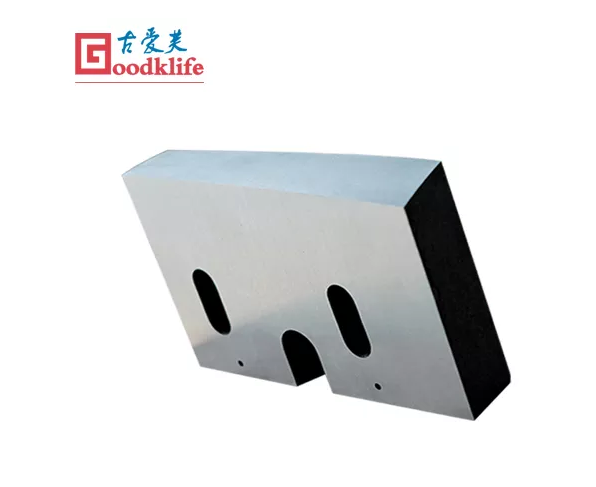

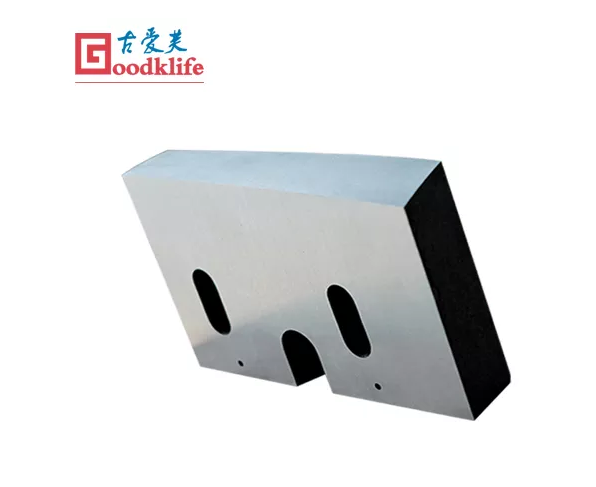

The role of the shredder is extremely important in the recycling of recycled resources. The shredder will shred, shear and crush the renewable materials. Because of the many types of waste, domestic waste and industrial waste are mixed together and sent to the waste disposal center, so it is very high requirements for the hardness and toughness of the blade material.

Steel knife materials can be broadly divided into three categories, namely carbide (tungsten carbide, TC), high-speed steel and alloy tool steel.

Carbide and HSS are mostly used for cutting materials such as silicon steel sheets, copper and aluminum and other non-ferrous metals, thinner stainless steel, etc.

Alloy tool steels are D2 (SKD11, 1.2379, KL31, G6), LD, H13 (SKD61, 1.2344, KL11, G15) and our patented material G1, etc., which are mainly used for cutting conventional non-ferrous metals, various carbon steels, stainless steels and high-strength steels.

When we choose a scrap shredding knife, it is mainly based on the power of the machine. For example, a shredder used to process metal is definitely larger than one for wood or rubber. Choose the right machine, then the blades used are naturally customized according to the actual material. Choose the right blade, not only to save costs, but also to enhance the efficiency of the stronger.

Blades are used in all different industries. Scrap shredders help protect employees from discarded blades.

The design of a scrap shredding knife is a technical task. From the selection of materials and the design of the machining process including heat treatment, it requires great skill and experience. Contact us and let's make progress together!

Choice of steel

The special characteristics of this kind of scrap chopper knives are reflected in the choice of steel, if the steel quality is poor, then the tool is very easy to damage. Since the resource recycling industry is usually very wide variety of waste, so people can not use a shredder to shred all the materials.

Steel knife materials can be broadly divided into three categories, namely carbide (tungsten carbide, TC), high-speed steel and alloy tool steel.

Carbide and HSS are mostly used for cutting materials such as silicon steel sheets, copper and aluminum and other non-ferrous metals, thinner stainless steel, etc.

Alloy tool steels are D2 (SKD11, 1.2379, KL31, G6), LD, H13 (SKD61, 1.2344, KL11, G15) and our patented material G1, etc., which are mainly used for cutting conventional non-ferrous metals, various carbon steels, stainless steels and high-strength steels.

When we choose a scrap shredding knife, it is mainly based on the power of the machine. For example, a shredder used to process metal is definitely larger than one for wood or rubber. Choose the right machine, then the blades used are naturally customized according to the actual material. Choose the right blade, not only to save costs, but also to enhance the efficiency of the stronger.

Scrap processing solutions

Scrap shredders can handle a wide variety of scrap materials and are used in a range of industries to improve production and processing. Their use varies depending on the industry and the scrap to be processed, but they can all improve efficiency while reducing waste and risk. GOODKLIFE shows some of the common scrap materials and how we handle them.Steel Strapping

Untreated steel strip scrap not only takes up a lot of space, but can be sharp and dangerous to handle. the GOODKLIFE scrap shredder solves both problems because the shredded steel strip is very compact and safer for employees to handle. Most importantly, the shredded scrap will help reduce dumpster fees.PET strapping

While unprocessed PET/polyethylene strapping does not present the same hazards as steel strapping, it still presents a tripping hazard, takes up a lot of space, and reduces productivity due to work space clutter. Loosely strapped bins can often be filled into drums after being shredded by the waste shredder, which improves efficiency and reduces housekeeping costs.

Blades

Handling blades used in a variety of different industries can be very dangerous for workers. In addition to processing blades into manageable scrap, the shredder further reduces risk by reducing the number of times workers must come into contact with these scrap blades.Blades are used in all different industries. Scrap shredders help protect employees from discarded blades.

Tube Industry

Choppers can easily handle pipe and pipe scrap conversions, providing a valuable service to help pipe mills recycle substandard pipe. Our blades handle pipe and tubing quickly and efficiently, and can handle all types of metals, including brass, copper and stainless steel.The design of a scrap shredding knife is a technical task. From the selection of materials and the design of the machining process including heat treatment, it requires great skill and experience. Contact us and let's make progress together!