Coil Slitting Process and the Importance of Blade Selection

Views : 2285

Update time : 2022-02-14 18:10:25

Coil slitting is the process of cutting wide metal coils into narrower coils. The cut piece is cut at a smaller width while maintaining the same length. Prior to slitting, the original coil is placed on an uncoiler drum for uncoiling and then flattened on a straightening machine in preparation for slitting.

Uncoiler: The main coil is loaded onto the uncoiler at the entrance of the machine. The uncoiler then uses an expandable mandrel to clamp the main coil to its inner diameter. The coil is rotated off the mandrel and the head of the coil is screwed into the edge guide of the machine.

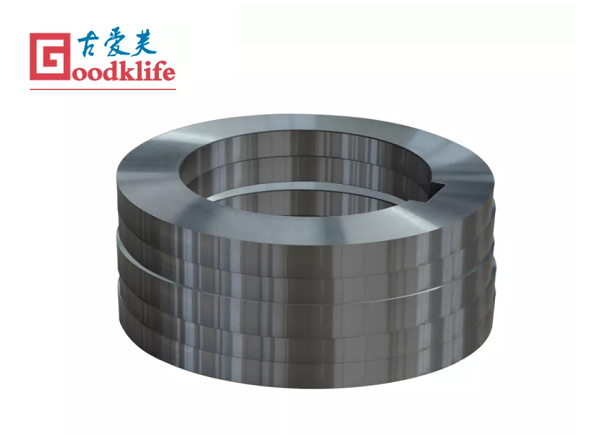

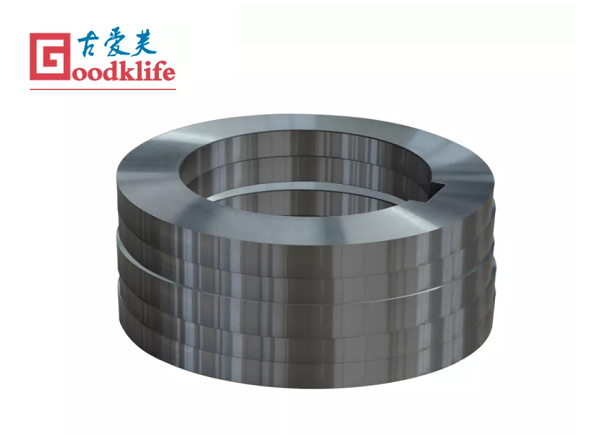

Slitter: The material is fed longitudinally into a slitter head consisting of two parallel mandrels. These parallel mandrels are fitted with a custom set of rotating slitting knives and rubber peel rings. The rubber rings help pull the material through the slitter mandrels while the knives penetrate the steel, causing the material to break or fracture.

The key to running an efficient precision coil slitting operation is setup. GOODKLIFE uses precision tooling and knives to ensure optimal cutting edges, and a computerized automation system to ensure spacing and horizontal tool clearance.

Recoiler : The main purpose of the Recoiler is to repackage the cut coils into coil form for packaging and shipping.

In order to achieve uniform results, the results must be evaluated and adjustments made for each operation. While each piece of metal has its own optimal tool clearance, achieving precise clearance is more challenging for thinner metals.

While some of these problems can be attributed to poor material quality, they are usually caused by irregularities that occur in the system during the web slitting process. For example, if the blades are set too tight or too far apart, the edges of the slit may become rough and uniform.

Therefore, the blade must be set correctly so that the line between the score and the break is straight and clean.

For example, for horizontal knife gaps, different gaps may be required if the same metal is not formed from the same source or has the same thickness.

For any coil to be divided precisely, tool and cutter clearances must be accurate. Therefore, it is important to have the machine checked regularly by an expert as well as to train the operator in its effective use.

Please follow GOODKLIFE to see more of our blades producat, and click the button to get the quote.

Coil slitting process

The slitter consists of three main parts: the uncoiler, the slitter mandrel/rotary knife and the rewinder.Uncoiler: The main coil is loaded onto the uncoiler at the entrance of the machine. The uncoiler then uses an expandable mandrel to clamp the main coil to its inner diameter. The coil is rotated off the mandrel and the head of the coil is screwed into the edge guide of the machine.

Slitter: The material is fed longitudinally into a slitter head consisting of two parallel mandrels. These parallel mandrels are fitted with a custom set of rotating slitting knives and rubber peel rings. The rubber rings help pull the material through the slitter mandrels while the knives penetrate the steel, causing the material to break or fracture.

The key to running an efficient precision coil slitting operation is setup. GOODKLIFE uses precision tooling and knives to ensure optimal cutting edges, and a computerized automation system to ensure spacing and horizontal tool clearance.

Recoiler : The main purpose of the Recoiler is to repackage the cut coils into coil form for packaging and shipping.

Rotary slitter knives for coil processing line

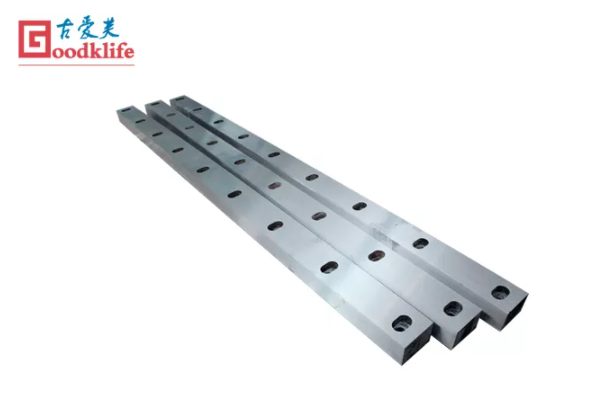

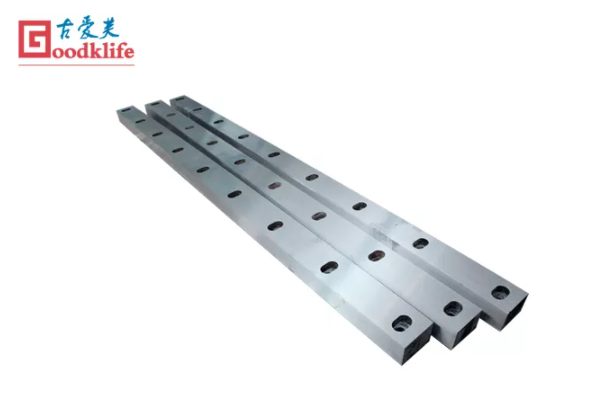

Blade configuration

Coil slitting can be applied to both rolls and sheets. The blades on the slitter must be adjusted to the tolerances that need to be maintained throughout the slitting process as well as the type and thickness of the material being slit.In order to achieve uniform results, the results must be evaluated and adjustments made for each operation. While each piece of metal has its own optimal tool clearance, achieving precise clearance is more challenging for thinner metals.

Slitting Problems

Problems with the slitting process include: wavy edges, crossbows, knife marks, burrs, curvature and inconsistent slit widths.While some of these problems can be attributed to poor material quality, they are usually caused by irregularities that occur in the system during the web slitting process. For example, if the blades are set too tight or too far apart, the edges of the slit may become rough and uniform.

Therefore, the blade must be set correctly so that the line between the score and the break is straight and clean.

Tooling influence

Tooling is one of the most important variables in the web slitting process. High-quality and well-maintained tools will ensure that fine edges are produced - but it is worth noting that despite advances in slitting equipment, there is no standard recipe for every material.For example, for horizontal knife gaps, different gaps may be required if the same metal is not formed from the same source or has the same thickness.

For any coil to be divided precisely, tool and cutter clearances must be accurate. Therefore, it is important to have the machine checked regularly by an expert as well as to train the operator in its effective use.

Please follow GOODKLIFE to see more of our blades producat, and click the button to get the quote.