Hydraulic nuts with high pressure grease pump

Hydraulic nuts can be divided into two categories from the pressure method.

One is to be by Allen Key with less pressure. Use a spanner to rotate a small screw on the outer circle or flat surface of the nut to squeeze the internal oil cavity space, thereby pushing the pressure ring to generate axial pressure. Due to the limited volume of the small screw, the compression flow that can be generated is naturally not large, and it is not enough to push the entire pressure ring to the necessary place. However, this nut has the advantages of convenient and concise operation. The nut is pressurized by Allen Key, and there is no need to fill and unload the oil throughout the process, which is conducive to keeping the work site clean and tidy. It is more suitable for trimming lines. One trimming line requires four hydraulic nuts. Each hydraulic nut only needs to lock one piece of blade. The pressure of the nut by Allen Key is sufficient to meet the requirements.

The second is to connect an external hand pump to pressurize. The manual pump is equipped with an accurate pressure gauge to facilitate the operator to accurately pressurize. With the same size, the axial pressure of the nut pressurized by the manual pump can be several times greater than that of the nut pressurized by the spanner, and the stroke is two to three times farther. For the wide slitting machine that slits multiple strips at one time, we only recommend the nut pressurized by an external hand pump, and the type by Allen Key cannot meet the requirements.

The core part of the entire slitting line is the cutter head, and the slitting tooling on the cutter head play a decisive role in the cutting effect. For the ultra-high-precision wide slitting machine, the number of strips can reach more than 60 at a time. The number of slitting tools on the knife shaft is often as many as several hundreds. How to make these loose tools form a rigid shear system? The hydraulic nut at the end of the cutter shaft plays a vital role. Qualified hydraulic nuts not only need to give enough axial pressure, but also to keep them from loosening and pressure relief during the entire shearing process.

According to the characteristics of the slitting system, GOODKLIFE focuses on the following points to ensure the use of hydraulic nuts successfully.

1.PRESSURE DISPLAY

We are equipped with pressure display indicator for the nuts by Allen Key. By observing the color of the indicator, you can quickly know the current pressure level of the nut.

The pressure nut by the manual pump is equipped with a pressure gauge, which is convenient for the operator to control the pressure of the nut.

2.PROFESSIONAL DESIGN

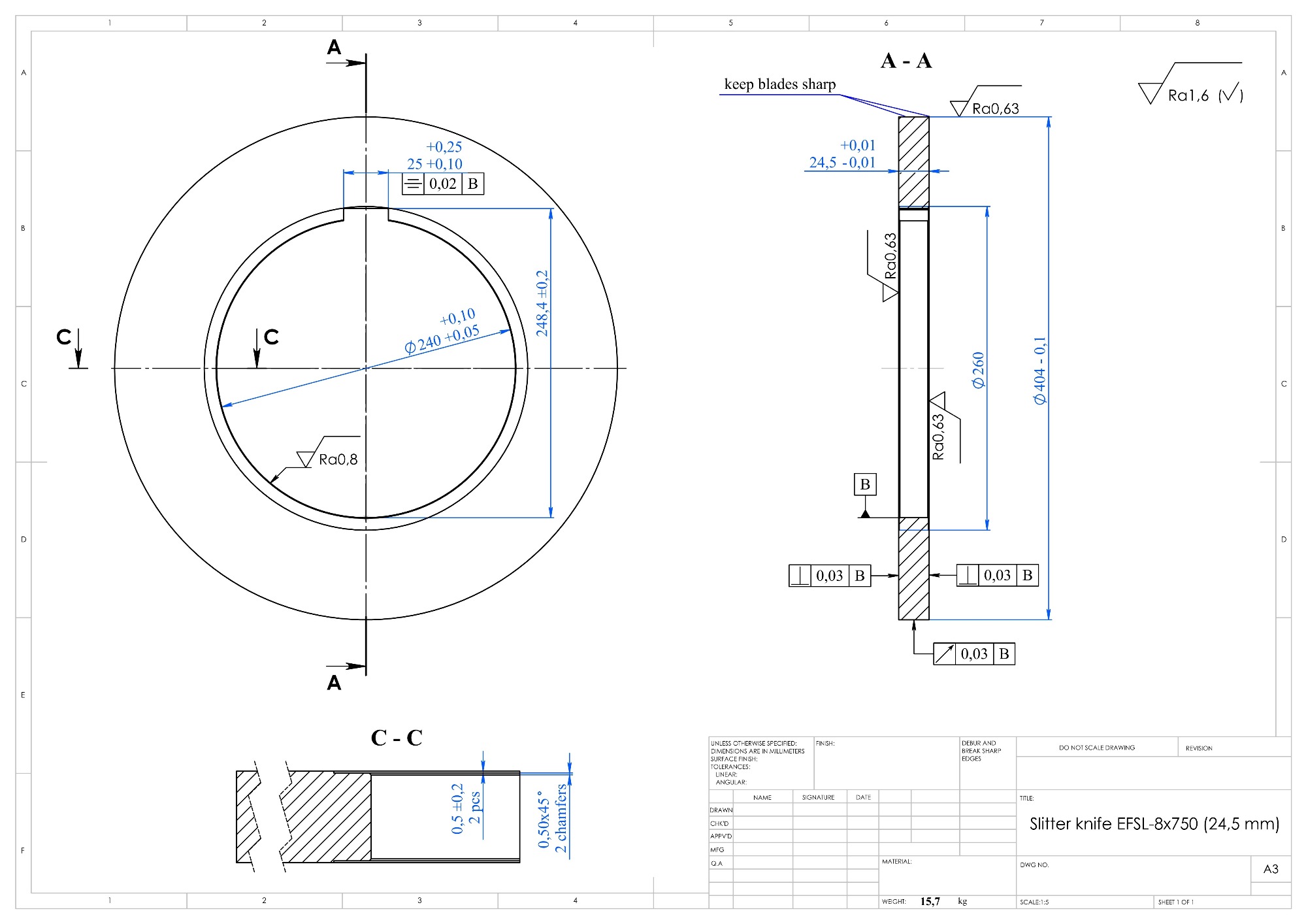

For a perfect hydraulic nut, we not only need to consider which pressurized method to choose, but also need to design its maximum pressure and maximum stroke. GOODKLIFE will design the key dimensions of the hydraulic nut according to the size of the customer's existing spacer ring, disc slitter blade, and rubber spacer ring. If necessary, our engineers will go to the site to analyze and inspect.

Only by choosing a suitable hydraulic nut can the rigidity of the entire cutting system, the correct position and clearance of the upper and lower blades, and the elimination of accumulated errors to a certain extent be ensured.

Products Show

Other slitting line products

Rubber bonded spacers |

Spacers |

Separator Discs |

Hydraulic Nuts |

Our Service

2.Solutions for special slitter-tooling, designed for your applications.

3.Technical service from our engineers to assist you in solve the problem of cutting edge and realizing a higher quality output.

4.On-site Inspection

5.Seminar and Training

We can custom blades according to your drawing or samples .

Packing & Delivery

Delivery Details :

5-50 days after receive your payment ,according to your quantity

Packing Details :

Outside : Packed in strong plywood case

Inside : With anti-rust oil in plastuc bag

If you have any inquiry , welcome to contact with us .

| Contact information | |||

|

|||