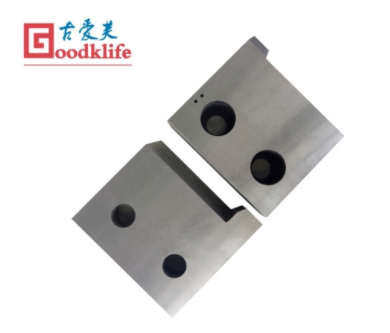

Shear Knives and Blades for Cutting Rebars

Views : 448

Update time : 2021-10-20 15:15:47

Steel reinforcement is one of the most important and commonly used materials in any construction project. It even has other uses besides its main purpose of reinforcing concrete. Different structures and applications require different lengths of steel. So most of the time rebar needs to be cut. Knowing how to cut rebar quickly and safely will help improve efficiency on site. There are many different tools that your staff can use to cut rebar. GOODKNIFE shares with you.

Metal shearing classification: In general, cutting units are classified as manual, automatic, hydraulic beams, guillotines and hydraulic CNC controls.

Hydraulic machines operate by moving the top and fixed blades, leaving appropriate cracks and applying some strength to the sheet of metal with a shear plate that fits into the previously planned dimensions of the shear plate.

Shears are manufactured for a wide range of uses in the light industry, shipbuilding, decorative industries, aviation and in the manufacture of electrical equipment and stainless steel products.

Cold forming rod cutting devices: this type of shear is particularly suitable for cold bending rods for automotive bundles, side shielding rods, coloured laminations, etc.

Metal shears are mainly used for the cutting of structural steel bars for steel frames, especially h-beams mechanical structural bars and angles.

You can clearly conclude that there is no single perfect method for cutting steel bars. There are many factors that you should consider when choosing a method. Some of these factors are: Time, number of bars, size of bars, quality of the result, budget, manpower expertise, accessibility of tools. Please contact us if you have any questions about shear blades and guillotine blades.

Shear blades

Sheet metal shears are imposed in sheet metal manufacturing because of their ability to cut sheet metal of various densities. Often referred to as a power shear or guillotine, the unit can be operated by foot or hand and can now be operated in rare use or hydraulically and automatically. During operation, it first presses the sheet by using a piston and then moves the blade to shear the plate on a fixed blade.Metal shearing classification: In general, cutting units are classified as manual, automatic, hydraulic beams, guillotines and hydraulic CNC controls.

Hydraulic machines operate by moving the top and fixed blades, leaving appropriate cracks and applying some strength to the sheet of metal with a shear plate that fits into the previously planned dimensions of the shear plate.

Shears are manufactured for a wide range of uses in the light industry, shipbuilding, decorative industries, aviation and in the manufacture of electrical equipment and stainless steel products.

Classification of shears

Special metal shears

This is often combined with alternative equipment to perform certain tasks:Cold forming rod cutting devices: this type of shear is particularly suitable for cold bending rods for automotive bundles, side shielding rods, coloured laminations, etc.

Metal shears are mainly used for the cutting of structural steel bars for steel frames, especially h-beams mechanical structural bars and angles.

Inclined shears

Sheet cutters have been supplied with top and bottom tools. The tops are usually inclined and are angled from 1" to 6". The angled cutter has less shear strength than a flat surface. This results in a considerable reduction in engine force and the overall Heft of the cutting unit.Flat blade shear

Good shear quality, low deformation, high shear strength and high energy consumption. The shear ridge of the unit is parallel. This is widely used for shearing hot ingots or bars.Universal shears

This machine, which combines punching and cutting is also known as an ironworker. This is suitable for shearing plates and cutting profiles, as well as in the hardening process. Combined plate benders can both shear and bend.You can clearly conclude that there is no single perfect method for cutting steel bars. There are many factors that you should consider when choosing a method. Some of these factors are: Time, number of bars, size of bars, quality of the result, budget, manpower expertise, accessibility of tools. Please contact us if you have any questions about shear blades and guillotine blades.