How to correctly determine the outer diameter difference between the circular slitter knife and the stripper ring?

Views : 9801

Author : Yuan Feng

Update time : 2022-04-11 12:04:23

To solve this problem, four factors should be considered:

The compression amount of the rubber ring is not absolute. It has a certain wide capacity, but it still has a basic formula for reference. The principle is that the center distance of the part of the knife should be equal to the center distance of the rubber ring, that is:

(diameter of male knife + diameter of female knife)/2 - amount of overlap of round knife

=(diameter of male ring + diameter of female ring)/2 - total compression of rubber ring + plate thickness

Total compression of rubber ring = (diameter of male ring + diameter of female ring)/2 - (diameter of male knife +

Female knife diameter)/2 + round knife overlap + plate thickness

= male ring radius increment - female ring radius decrement +

sheet thickness + round knife overlap

The use of this basic formula is as follows:

If the diameter of the male ring is 0.5 mm larger than that of the circular knife, and the diameter of the female ring is 0.5 mm smaller than that of the circular knife, the plate thickness is 0.5 mm, and the overlap is 0.1 mm (20%), then the total compression of the male and female rings is: 0.5 mm/2- 0.5 mm/2+0.4 mm+0.1 mm=0.5 mm. The respective compression of the male and female rings is: 0.5 mm/2 = 0.25 mm which should be more reasonable.

The detailed method is:

c. Convert the formula, female ring radius decrement = male ring radius increment - total compression of rubber ring + thickness of plate + overlap of circular knife.

Assumption: the diameter increment of male ring is still 0.5 mm, the radius increment is 0.25 mm, the thickness of sheet is 1.5 mm, the overlap is 0.3 mm (20%), and the total compression is slightly increased due to the thick plate, which is 1.2 mm (male and female rings 0.6 mm each).

Decrement in female ring radius = 0.25 mm - 1.2 mm + 1.5 mm + 0.3 mm = 0.35 mm, female ring diameter decrement = 0.7 mm.

Use the formula used in the first case to calculate the total compression of the thinnest and thickest materials, and check whether the compression of the male and female rings is between the appropriate compression. Otherwise, it is necessary to adjust the male ring increment, or it is recommended to increase the number of female rings. Using the formula used in the second case to calculate the diameter decrement of the female ring, it should also be adjusted according to the thickness of the plate that is often sheared.

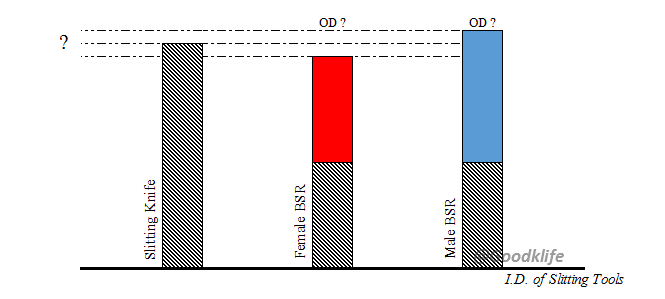

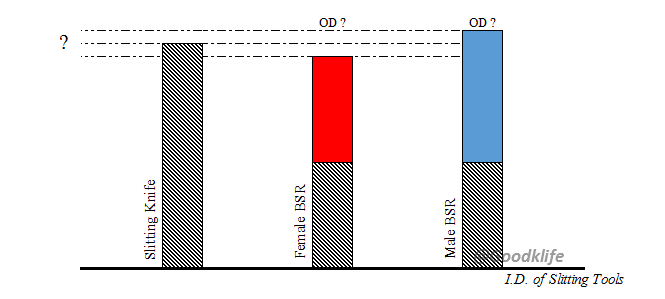

O.D. of Stripper Rings for Slitting Line

1. During slitting, the rubber stripper rings on the side of the female knife and the male knife are compressed, and the compression amount of the two is basically the same. The amount of compression should not be too small, it should at least cover the eccentricity of its inner and outer circles, and it should be able to control the direction of the sheet after slitting, but it should not be too large. If it is too large, the cutter shaft of the slitting machine will be overstressed . According to personal experience, within the working range of coil thickness of 0.1 - 3 mm, the min. compression amount is that the rubber part can still hold the strip under the circumstance that the outer circle of the rubber stripper ring is eccentric, and the maximum should not exceed 1 mm. The compression amount of thin coils should be smaller to avoid wrinkling of the strip. The compression amount of thick coils should be larger, but it should not exceed 1 mm. When the compression amount exceeds 1 mm, the compression amount of the rubber stripper ring is too large. In addition to the excessive load of the cutter shaft, the rubber ring is easily fatigued and damaged during the repeated compression and relaxation process, reducing the service life. It is recommended to add an extra set of female rubber stripper rings to rebalance the compression of each set of rubber rings.

2. The outer diameter of the rubber ring on the male knife side is larger than that of the knife, and the outer diameter of the rubber ring on the female knife side is smaller than that of the knife, so that when the material to be cut is under pressure, the male knife side is consciously and dynamically moved. The outer diameter of the rubber ring pushes the strips out of the cutting area.

3. When considering the outer diameter of the rubber stripper ring, the compression amount added after the sheet enters the nip must be considered, and this compression amount must cover a certain thickness range of the sheet. If it cannot be covered, add a set of rubber rings on the side of the female knife.

4. Due to the influence of investment and production management, it is impossible to increase the number of groups of rubber rings on the side of the female knife without limit. Therefore, when adding rubber rings, it is necessary to select the appropriate compression amount as much as possible, but in actual production, there are still It is necessary to adjust the amount of blade overlap to accommodate the inherent compression of the rubber ring. The two are the unity of contradictions, which must be adapted and adjusted to each other.

The compression amount of the rubber ring is not absolute. It has a certain wide capacity, but it still has a basic formula for reference. The principle is that the center distance of the part of the knife should be equal to the center distance of the rubber ring, that is:

(diameter of male knife + diameter of female knife)/2 - amount of overlap of round knife

=(diameter of male ring + diameter of female ring)/2 - total compression of rubber ring + plate thickness

Total compression of rubber ring = (diameter of male ring + diameter of female ring)/2 - (diameter of male knife +

Female knife diameter)/2 + round knife overlap + plate thickness

= male ring radius increment - female ring radius decrement +

sheet thickness + round knife overlap

The use of this basic formula is as follows:

1. In specific production, find the total compression amount of the rubber ring when the items on the right side of the equation are known.

If the diameter of the male ring is 0.5 mm larger than that of the circular knife, and the diameter of the female ring is 0.5 mm smaller than that of the circular knife, the plate thickness is 0.5 mm, and the overlap is 0.1 mm (20%), then the total compression of the male and female rings is: 0.5 mm/2- 0.5 mm/2+0.4 mm+0.1 mm=0.5 mm. The respective compression of the male and female rings is: 0.5 mm/2 = 0.25 mm which should be more reasonable.

2. The thickness range of the plate is known, and the diameter of the male ring and the diameter of the female ring should be determined during grinding.

The detailed method is:

a. Select the middle thickness of the plate. For thin materials with a thickness of 0.5 ~ 3 mm, the coverage of each group of female knives is at most 1 mm. The arrangement should be 0.5 ~ 1 mm for the first group, 1-2 mm for the second group, 2~3 mm is the third group.

b. First assume the radius increment of the male knife and the total compression of the rubber stripper ring.

c. Convert the formula, female ring radius decrement = male ring radius increment - total compression of rubber ring + thickness of plate + overlap of circular knife.

Assumption: the diameter increment of male ring is still 0.5 mm, the radius increment is 0.25 mm, the thickness of sheet is 1.5 mm, the overlap is 0.3 mm (20%), and the total compression is slightly increased due to the thick plate, which is 1.2 mm (male and female rings 0.6 mm each).

Decrement in female ring radius = 0.25 mm - 1.2 mm + 1.5 mm + 0.3 mm = 0.35 mm, female ring diameter decrement = 0.7 mm.

Use the formula used in the first case to calculate the total compression of the thinnest and thickest materials, and check whether the compression of the male and female rings is between the appropriate compression. Otherwise, it is necessary to adjust the male ring increment, or it is recommended to increase the number of female rings. Using the formula used in the second case to calculate the diameter decrement of the female ring, it should also be adjusted according to the thickness of the plate that is often sheared.

O.D. of Stripper Rings for Slitting Line