Do You Know How Rubber Rings Are Made?

Views : 340

Update time : 2021-11-18 15:10:13

One of the most common rubber needs of manufacturers is the bonding of rubber to metal. When metal is bonded to rubber, it becomes very strong and durable. This becomes very important in coil processing and cutting applications. Manufacturers are able to select materials to produce rubber ring gaskets based on the heat resistance, durability and other properties required for the intended application. Read on to learn more.

Automotive: gaskets, seals, bushings, engine mounts, hangers, bumpers

Slitting line: in combination with other slitting line tools such as slitting knives, steel spacers, separating discs, separating spacers, etc.

Medical: O-rings, piping, extrusions, pump compressor isolation

Public transportation: valve seals, pedals, suspensions, engine parts

Structural: Conveyor belts, dampers, isolation brackets, stabilizers

Metal bonding ensures the highest level of safety. Bonding metal to rubber parts can last a long time, ensuring the safety of users and equipment. Optimal results can be achieved with the right materials.

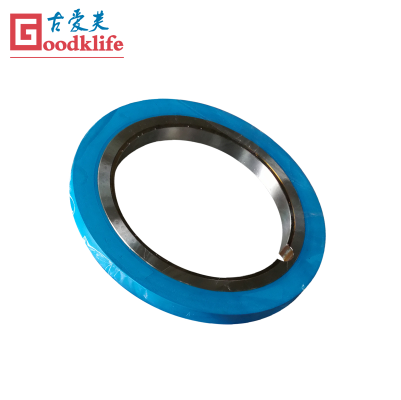

Rubber bonded spacer

Natural rubber (NR), fluoroelastomer (FKM), ethylene propylene (EPDM), nitrile (NBR), chloroprene (CR), and silicone (VMQ).

Steel, Aluminum, Brass, Beryllium, and Copper.

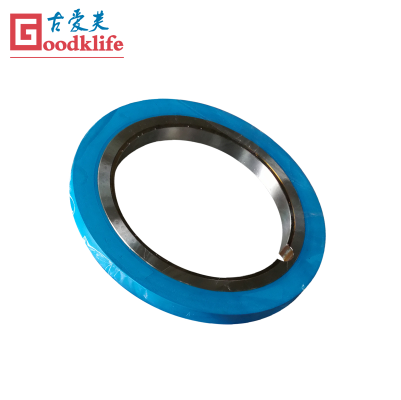

Dual durometer rubber stripper rings

Goodklife specializes in shear blades, slitting knives, flying shear blades, scrap steel shear blades and other industrial blades. Goodklife can recommend the right material and hardness for your application, and can also achieve single and dual hardness. If you are looking for a partner about shear line tools, please contact us for customized service.

Rubber Ring Gasket Applications

Metal bonding can be performed on virtually any rubber part. That's what makes it so versatile and popular. There are many uses for metal bonding rubber. Here are a few.Automotive: gaskets, seals, bushings, engine mounts, hangers, bumpers

Slitting line: in combination with other slitting line tools such as slitting knives, steel spacers, separating discs, separating spacers, etc.

Medical: O-rings, piping, extrusions, pump compressor isolation

Public transportation: valve seals, pedals, suspensions, engine parts

Structural: Conveyor belts, dampers, isolation brackets, stabilizers

Metal bonding ensures the highest level of safety. Bonding metal to rubber parts can last a long time, ensuring the safety of users and equipment. Optimal results can be achieved with the right materials.

Rubber bonded spacer

Rubber-to-metal gasket materials

There are many different materials available for the rubber-to-metal bonding process. Take a look at the different types of rubber and metal materials that can be used for bonding.Rubber

There are a variety of options for rubber materials or polymers that can be bonded to metals. Manufacturers choose polymers based on the properties they are looking for. For example, if a manufacturer needs a particularly flexible polymer, they may choose silicone. These are the six most common rubbers used for metal-rubber bonding.Natural rubber (NR), fluoroelastomer (FKM), ethylene propylene (EPDM), nitrile (NBR), chloroprene (CR), and silicone (VMQ).

Metals

There are many metal options for rubber bonding. OEMs will choose the type of metal based on the application they need the rubber part for. If the manufacturer is looking for an inexpensive, durable material, then they may choose aluminum. The following are five common metal surface options used in molded rubber parts.Steel, Aluminum, Brass, Beryllium, and Copper.

Dual durometer rubber stripper rings

Goodklife specializes in shear blades, slitting knives, flying shear blades, scrap steel shear blades and other industrial blades. Goodklife can recommend the right material and hardness for your application, and can also achieve single and dual hardness. If you are looking for a partner about shear line tools, please contact us for customized service.