Commonly Used Tools in Precision Slitting

Views : 600

Author : Wallivia

Update time : 2022-06-13 15:01:08

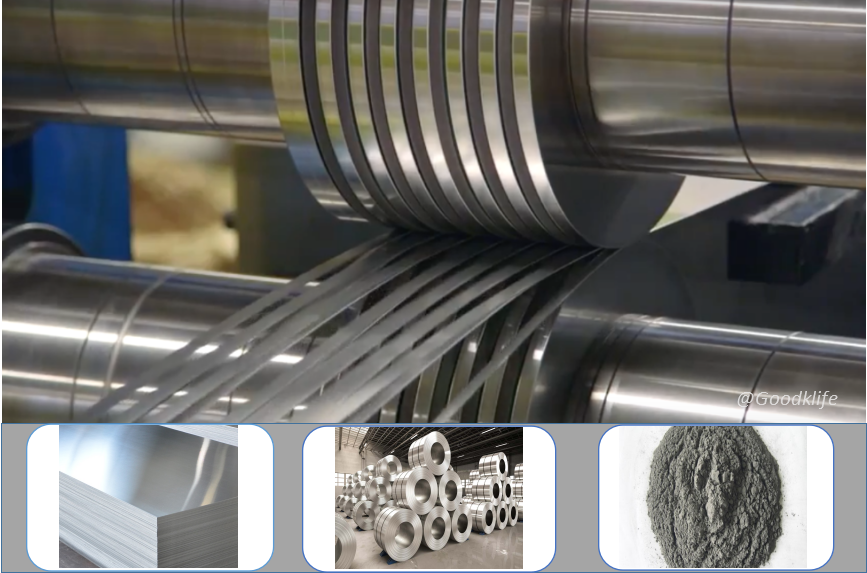

Precision slitting is a web processing service in which a master web is fed into the machine and then cut to the length and width required by the specification.

As the material moves through the machine, extremely sharp circular blades (also called knives) mounted on spacers cut at the desired location. The rubber peel ring serves a dual purpose, supporting the material as the slitting proceeds and then ejecting the finished strip from between the blades.

Slitting line tool suppliers introduce you to some common basic tools.

As the material moves through the machine, extremely sharp circular blades (also called knives) mounted on spacers cut at the desired location. The rubber peel ring serves a dual purpose, supporting the material as the slitting proceeds and then ejecting the finished strip from between the blades.

Slitting line tool suppliers introduce you to some common basic tools.

Precision Slitting

When you need to cut steel coils to tight tolerances, there is no better tool than a precision slitting line. This process is known for its ability to cut material to specified lengths and widths with superior precision, eliminating material waste and saving money.

Getting the coil in the length, width or edge you want can dramatically benefit your business. It maximizes the use of available material while reducing additional handling, which can increase costs and delay turnaround times. This can lead to unnecessary downtime.

Getting the coil in the length, width or edge you want can dramatically benefit your business. It maximizes the use of available material while reducing additional handling, which can increase costs and delay turnaround times. This can lead to unnecessary downtime.

Shear Blades

Shear blades are typically used in applications and industries that require precise cutting. While setting up shear slitting can be both expensive and difficult, it is effective in converting thick films, paper, foil, composites and layered materials. The shear slitting process requires two blades, one at the top and one at the bottom. The top blade is called the "male cutter" and the bottom is called the "female blade" or "anvil holder". Like a hand shear, the two blades converge to a single cutting point. This slitting process generates the least amount of heat, which is why it is often used in environments that require demanding operation and uptime.

The best way to maintain these blades is to make sure the cutting point is accurate. If not set correctly, the blades will wear out faster than usual. In addition, blades can be sharpened to increase the life of shear slitting knives.

The best way to maintain these blades is to make sure the cutting point is accurate. If not set correctly, the blades will wear out faster than usual. In addition, blades can be sharpened to increase the life of shear slitting knives.

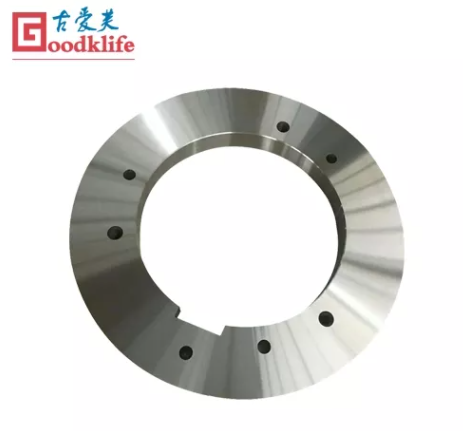

Rotary Slitting Blades

Rotary slitting blades or circular slitting knives are the type of blade with a sharp cutting edge. They usually have a low cutting angle and no teeth. As the name implies, round slitting blades are mainly used for slitting type cutting operations.

GOODKLIFE manufactures and supplies thousands of precision circular slitting knives and rotary slitting inserts in standard and custom sizes for most applications. Whether you need top and bottom or disc-shaped circular blades, or blades with teeth, serrated, scalloped, perforated and serrated forms, or even more complex tooth forms. Whether it's paper cutting, food slicing, packaging, rubber processing, meat cutting, film cutting or foil processing, whatever the application, our round knives and blades are made of high quality grind-hardened tool steel and stainless steel.

GOODKLIFE manufactures and supplies thousands of precision circular slitting knives and rotary slitting inserts in standard and custom sizes for most applications. Whether you need top and bottom or disc-shaped circular blades, or blades with teeth, serrated, scalloped, perforated and serrated forms, or even more complex tooth forms. Whether it's paper cutting, food slicing, packaging, rubber processing, meat cutting, film cutting or foil processing, whatever the application, our round knives and blades are made of high quality grind-hardened tool steel and stainless steel.

Stripper Rings

The peel ring is a key component in the slitting process. We offer all types of peel rings and custom cladding rings for ultra-sensitive surfaces.

Rubber stripper rings are available in single or dual durometer polyurethane, NBR and nylon. All materials are available in a wide range of durometer and color options. We are an excellent resource for the correct size of rubber release rings.

Our steel release rings are made of bearing grade tool steel with a polished outside diameter. All rings are engraved with clear etchings for easy identification.

Stripper rings assist in a variety of tasks for cutting applications.

Ejecting

Conveying

Lifting (protects material surface)

Support (stabilizes the material)

Steel stripping rings made of hardened alloy tool steel are used for thin materials and the narrowest strips, provided that the design of the slitting line allows this use.

Rubber stripper rings are available in single or dual durometer polyurethane, NBR and nylon. All materials are available in a wide range of durometer and color options. We are an excellent resource for the correct size of rubber release rings.

Our steel release rings are made of bearing grade tool steel with a polished outside diameter. All rings are engraved with clear etchings for easy identification.

Stripper rings assist in a variety of tasks for cutting applications.

Ejecting

Conveying

Lifting (protects material surface)

Support (stabilizes the material)

Steel stripping rings made of hardened alloy tool steel are used for thin materials and the narrowest strips, provided that the design of the slitting line allows this use.