7 Common Steel Materials for Slitting Knives

Views : 459

Update time : 2022-01-08 15:59:54

Different hydraulic shear manufacturers will use different steels to produce their blades. To get the best shear blades, you need to know the following 7 common hydraulic shear blade materials.

It is commonly used in the manufacture of hydraulic shear blades that are subjected to impact loads and require high wear resistance, and is suitable for a variety of common steel and hard stainless steel plate shears.

It is suitable for the manufacture of poor cutting conditions, high wear resistance requirements, not subject to sudden and violent vibration, the need for a certain degree of toughness and sharp knife edge shear blades, for ordinary A3 plate cutting.

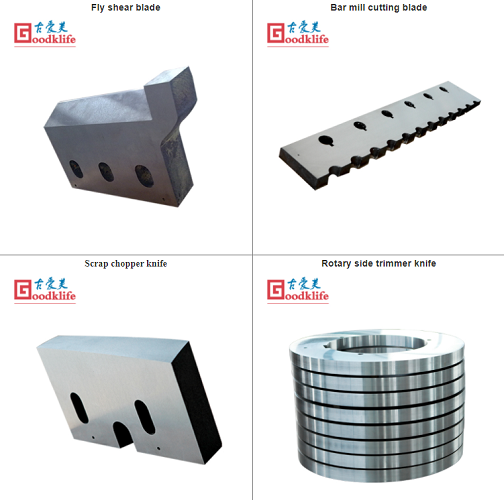

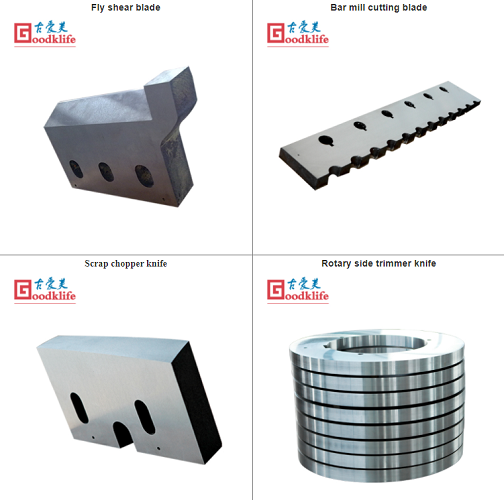

Goodklife is one of the most famous town for blades in China, we have more than 30 years experience in this line. The company has been committed to providing knives and blades of high productivity and high precision. From raw material, heat treatment to finishing, Goodklife keeps track and exercises strict control over every piece, in order to improve the performance of our products and production efficiency, at the same time reduce the production cost.

Please contact us today to get your blade and we offer professional solution for you.

Cold work tool steel

LD is a high quality, high toughness cold work tool steel originally used for cold heading tool development. According to the actual production experience, LD steel is used to make cold heading, cold extrusion, cold die that requires high toughness. It has high strength, high flexural strength, small heat treatment deformation and high versatility. It has high strength and toughness, good wear resistance, and can be used to make various cold cutting scissor blades.Hot work die steel

H13 steel is a high-quality air-cooled hardening die steel. It has high toughness and resistance to hot and cold fatigue, not easy to produce thermal fatigue cracks, strong resistance to adhesion, molten metal interaction is small, widely used in hot upsetting, hot extrusion, hot shear blade manufacturing. It is the representative steel used in hot work tool steel, suitable for hot shear of steel plate with temperature below 800°.Alloy Tool Steel

6CrW2Si is a high quality alloy tool steel, which is based on chromium-silicon steel with a certain amount of tungsten. It has higher toughness under tempering conditions because tungsten helps to maintain relatively fine grain size during quenching.It is commonly used in the manufacture of hydraulic shear blades that are subjected to impact loads and require high wear resistance, and is suitable for a variety of common steel and hard stainless steel plate shears.

High-speed tool steel

W6Mo5Cr4V2 is a high quality high-speed tool steel, referred to as 6542, commonly known as "high-speed steel", is a high-carbon, high-alloy tool steel for high-speed cutting. Tungsten molybdenum series is the representative of high speed steel, its outstanding features are high hardness, wear resistance and hot hardness. It is mainly used to make cutting inserts with high cutting speed, heavy load and high working temperature, and is suitable for shearing plates in various states.Die Steel

Cr12MoV is a high quality die steel with good hardenability, high hardness, strength and toughness after tempering. It can be completely hardened, quenching deformation is small, but the high temperature plasticity is poor. It is mainly used for the production of hydraulic scissor blades with large cross-section, complex shape, large workload, etc. It is suitable for cutting stainless steel plates, silicon steel sheets and other high hardness plates.Carbon tool steel

T10A is a high-quality carbon structural steel, high strength and wear resistance, but low thermal hardness, low hardenability, quenching deformation.It is suitable for the manufacture of poor cutting conditions, high wear resistance requirements, not subject to sudden and violent vibration, the need for a certain degree of toughness and sharp knife edge shear blades, for ordinary A3 plate cutting.

Steel carbon structural steel

45# is a high-quality carbon structural steel, widely used in machinery manufacturing. It has the characteristics of easy cutting and has good mechanical properties. However, 45# steel, as a medium carbon steel, has poor quenching properties and is used for manufacturing shearing machine blades. Therefore, the usual practice is to use the quenching + high frequency surface quenching process. The wear resistance is slightly worse than carburizing and is suitable for non-metal plate shearing.Goodklife is one of the most famous town for blades in China, we have more than 30 years experience in this line. The company has been committed to providing knives and blades of high productivity and high precision. From raw material, heat treatment to finishing, Goodklife keeps track and exercises strict control over every piece, in order to improve the performance of our products and production efficiency, at the same time reduce the production cost.

Please contact us today to get your blade and we offer professional solution for you.