How to choose material for slitter knives, chopper knives and straight blades for medium and heavy gauge metal plate?

Views : 3627

Author : Mr. Jiang

Update time : 2021-02-21 21:03:18

The wear resistance and precision of cutting tools is crucial for thin coils cutting. How about for medium and heavy gauge metal plate ( usually with thickness more than 4.5mm), especially for ultra high tensile strength (UHTS) coils? The first challenge is avoiding knife crack which means the knife should be good enough for its toughness and ductility. Good toughness and ductility are not enough. The knife should also be good for wear resistance. Thus the knife has long work life.

As we all know, TC, HSS or some alloy tool steels like D2 is very good for their wear resistance. But for heavy gauge application, all of them cannot work because of not enough toughness and ductility. Nowadays, H13 (equivalent to DIN 1.2344, W302 Böhler Martin Miller, JIS SKD61) is widely used for cutting medium and heavy gauge metal plate all over the world, no matter for cold or hot cutting.

The characteristics of H13 are as following:

> High hardenability and high toughness.

> Excellent thermal crack resistance, water cooling can be used in the work place.

> With moderate wear resistance, carburizing or nitriding can also be used to increase the surface hardness, but the thermal crack resistance should be slightly reduced.

> It has the ability to resist softening at higher temperatures, but the hardness drops rapidly when the use temperature is higher than 540°C (1000°F) (that is, the capable working temperature is 540°C).

> Small deformation in heat treatment.

> Medium and high machinability;

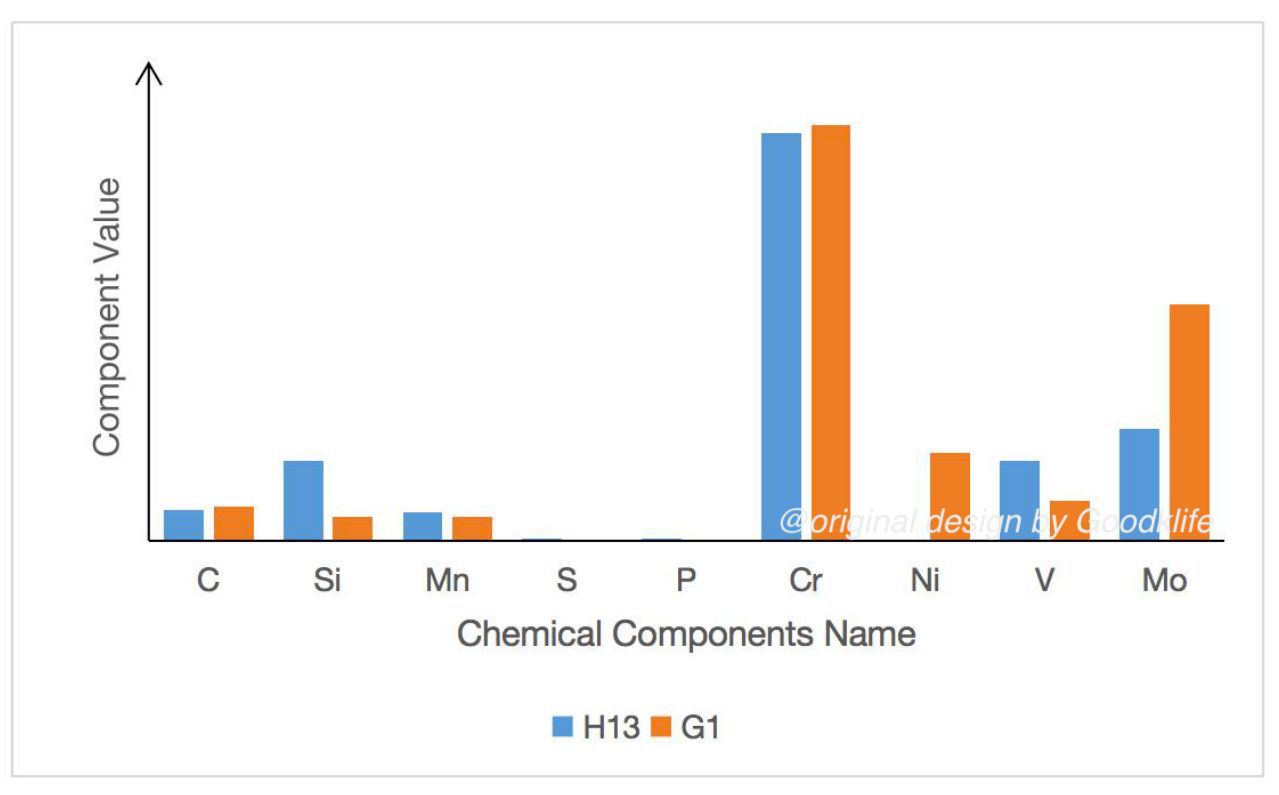

However, with the rapid development of the metal processing industry, the wear resistance of H13 has long been unable to meet the requirements. In addition, H13 can not meet the shearing conditions under high temperature conditions, and the knives and blades are often unable to continue to be used because of the dropping hardness. For this reason, Goodklife and several university professors developed G1 high-alloy tool steel and obtained a national patent. This material solves the problem of insufficient wear resistance and high temperature resistance of H13. Figure 1 shows the difference of chemical components between G1 and H13. G1 is a ESR remelt high alloy tool steel. The value of P and S is extremely low in G1 material, below 0.0025, while G1 has more W and Ni, which can increase wear resistance and toughness.

The characteristics of G1 are as following:

> Excellent wear resistance.

> Good toughness.

> Good stability in heat treatment.

> Excellent hot hardness (can be used in higher temperature working condition).

> Excellent through-hardening properties.

Since G1 was developed, it has been used all over the world for nearly 20 years. The performance is excellent. Figure 2 and 3 shows feedback from two of our clients who use our G1 material regularly.

The Case of Figure 2

* Case Study: Slitting Knives

* Client: Coils Producer (Italy)

* Processed material: Hot rolled carbon steel material from thk.3 mm up to 16 mm.

* Maximum tensile strength = 900 N/mm2

* Blade material: G1-ESR, core hardened at 54-57 HRC (HRC 55/56)

Feedback from Client in Italy: Comparing with K306 Böhler Martin Miller, the slitting performance of our G1 increased by 250%.

The Case of Figure 3

* Case Study: Flying Shear

* Client: Deformed Bar Producer (Norway)

* Processed material: B 500 NC (according to NS 3576-) with a yield point between 500-650 MPa, dimensions 10-32 mm. A 700 HW (according to DS/EN 10080) in dimensions 12-20 mmwith a yield point up to 700 MPa.

* Max tempreture 600°C

* Maximum tensile strength = 700 N/mm2

* Blade material: G1 – ESR, core hardened at 52-55 HRC (HRC 53/54)

Feedback from Client in Norway: Comparing with H13, the cutting performance of our G1 increased by 200%.

For more information of our G1 material, you are welcome to contact us anytime. We are also actively looking for broader cooperation. As long as you are a steel mill with a certain scale, a well-known local metal processing or manufacturer, you will have the opportunity to use our G1 sample products for free.

As we all know, TC, HSS or some alloy tool steels like D2 is very good for their wear resistance. But for heavy gauge application, all of them cannot work because of not enough toughness and ductility. Nowadays, H13 (equivalent to DIN 1.2344, W302 Böhler Martin Miller, JIS SKD61) is widely used for cutting medium and heavy gauge metal plate all over the world, no matter for cold or hot cutting.

The characteristics of H13 are as following:

> High hardenability and high toughness.

> Excellent thermal crack resistance, water cooling can be used in the work place.

> With moderate wear resistance, carburizing or nitriding can also be used to increase the surface hardness, but the thermal crack resistance should be slightly reduced.

> It has the ability to resist softening at higher temperatures, but the hardness drops rapidly when the use temperature is higher than 540°C (1000°F) (that is, the capable working temperature is 540°C).

> Small deformation in heat treatment.

> Medium and high machinability;

However, with the rapid development of the metal processing industry, the wear resistance of H13 has long been unable to meet the requirements. In addition, H13 can not meet the shearing conditions under high temperature conditions, and the knives and blades are often unable to continue to be used because of the dropping hardness. For this reason, Goodklife and several university professors developed G1 high-alloy tool steel and obtained a national patent. This material solves the problem of insufficient wear resistance and high temperature resistance of H13. Figure 1 shows the difference of chemical components between G1 and H13. G1 is a ESR remelt high alloy tool steel. The value of P and S is extremely low in G1 material, below 0.0025, while G1 has more W and Ni, which can increase wear resistance and toughness.

The characteristics of G1 are as following:

> Excellent wear resistance.

> Good toughness.

> Good stability in heat treatment.

> Excellent hot hardness (can be used in higher temperature working condition).

> Excellent through-hardening properties.

Since G1 was developed, it has been used all over the world for nearly 20 years. The performance is excellent. Figure 2 and 3 shows feedback from two of our clients who use our G1 material regularly.

The Case of Figure 2

* Case Study: Slitting Knives

* Client: Coils Producer (Italy)

* Processed material: Hot rolled carbon steel material from thk.3 mm up to 16 mm.

* Maximum tensile strength = 900 N/mm2

* Blade material: G1-ESR, core hardened at 54-57 HRC (HRC 55/56)

Feedback from Client in Italy: Comparing with K306 Böhler Martin Miller, the slitting performance of our G1 increased by 250%.

The Case of Figure 3

* Case Study: Flying Shear

* Client: Deformed Bar Producer (Norway)

* Processed material: B 500 NC (according to NS 3576-) with a yield point between 500-650 MPa, dimensions 10-32 mm. A 700 HW (according to DS/EN 10080) in dimensions 12-20 mmwith a yield point up to 700 MPa.

* Max tempreture 600°C

* Maximum tensile strength = 700 N/mm2

* Blade material: G1 – ESR, core hardened at 52-55 HRC (HRC 53/54)

Feedback from Client in Norway: Comparing with H13, the cutting performance of our G1 increased by 200%.

For more information of our G1 material, you are welcome to contact us anytime. We are also actively looking for broader cooperation. As long as you are a steel mill with a certain scale, a well-known local metal processing or manufacturer, you will have the opportunity to use our G1 sample products for free.

Fig. 1 Comparison of Chemical Components between H13 and G1

Fig. 2 Performance Comparison of Slitting Knives Made of K306 and G1

Fig. 3 Performance Comparison of Flying Shear Blades Made of H13 and G1